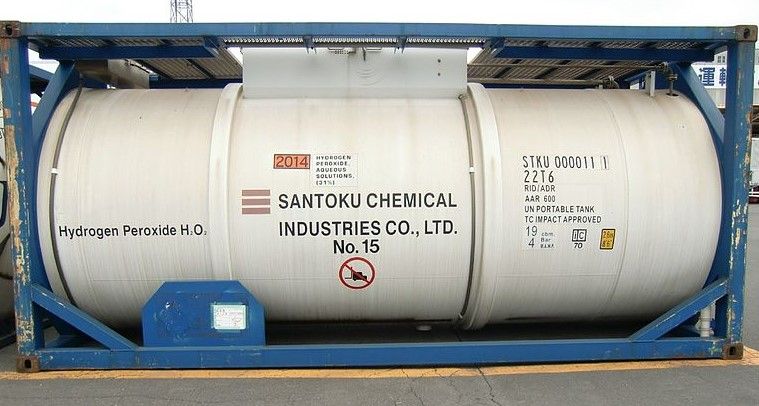

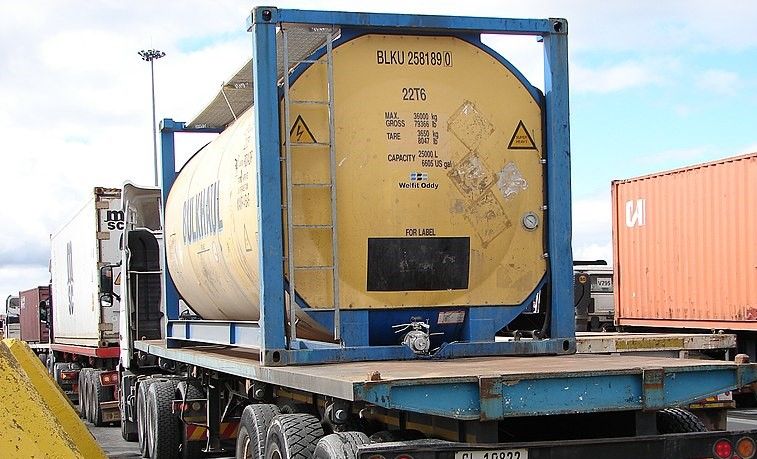

ISO Tank Containers are intermodal containers for the bulk cargo transportation of liquids, gases, and powders. They are commonly called a ‘tanktainers’ and gain the ISO in their name from the ISO standards that it must adhere to.

To the untrained eye they may look like simply metal cans, however their structure is more scientific, and their manufacturing is more highly engineered than first imagined.

Specifically, they are stainless-steel vessels which come in a variety of sizes but most commonly measure 6.05m by 2.4m and 2.55m tall (similar to a standard shipping container). For insulation and protection, the steel is encased in a layer of polyurethane and aluminium, all kept inside a steel framework.

They can handle a payload of 32,350kg, a volume of between 17,500 and 26,000 litres, at a pressure of 4 Bar, and at a maximum temperature of 120°C.

It is difficult to know how many ISO containers there are in the world, but there are believed to be about 800,000 in use at any one time.

While they are modest steel containers, they are in fact the unsung heroes of the chemical industry and have grown to be an essential part of the logistics sector. This is due to the following reasons:

1. Utility: ISO tanks are capable of carrying a large range of raw materials, including bulk liquids, toxic chemicals, catalysts, and intermediates. They also keep contaminants out, and are thus suitable for more sensitive chemical products, such as food additives and flammable ingredients. This adaptability is a big benefit for sectors with different cargo needs, such as the chemical industry.

2. Safety: ISO tanks adhere to strict safety regulations, as they can be fitted with safety measures including spill containment systems, emergency venting, and pressure relief valves to guarantee the secure transportation of hazardous products and chemicals.

3. Cost-effectiveness: Because ISO tanks do not require packing materials like chemical drums or barrels, they are a cost-effective option. Their simple use also reduces handling fees, lowers cleaning costs, and removes packaging disposal requirements.

4. Eco-friendly: With less packaging and an easily reusable container, ISO tanks help to promote environmental sustainability.

While there are many advantages to using ISO tanks, there are also certain challenges that need to be resolved for the safe and efficient shipping of industrial chemicals. These include:

1. Container Availability.

Demand for ISO tanks can fluctuate greatly due to local circumstances and global economic influences. In times of shortage, chemical supplies can be delayed due to a lack of container availability. Conversely, an oversupply of containers can lead to a considerable fall in price.

As a result, effective supply chain management is essential to ensure a smooth flow of chemical product from raw material supplier to customer.

2. Regulatory Adherence.

Hazardous chemical and raw material transportation is governed by a variety of laws, both international and maritime, as well as the varied laws set by each nation. Ensuring conformity to these standards in the country of origin, the destination country, and everywhere passed through in between, is complex and time-consuming.

If the rules are not followed then the deliverer risks being fined, having the shipment delayed until compliance is met, or even having the cargo seized.

Using an ISO tank ensures a better chance of regulatory compliance but will not cover all possibilities.

3. Maintenance and Inspection.

To stop leaks, corrosion, and structural damage, ISO tanks need to have regular maintenance and inspections performed. Inadequate maintenance can result in accidents, loss of chemical product, environmental damage, personal injury or health risks, as well as economic loss.

It is advisable for raw material suppliers and those responsible for delivering chemical goods to establish and follow strict maintenance plans.

4. Freight Compatibility.

It is important to make sure the ISO tank is appropriate for the goods/chemical products being transported, especially in the case of toxic or combustible chemicals.

Incompatibilities may occur if the tank was previously used to carry a different raw material or chemical. Safety standards could be compromised by contamination or chemical reaction from residues of the previous delivery reacting with the current payload. To reduce these dangers, thorough cleaning and certification is necessary.

“By confronting these challenges head-on, the ISO tank industry ensures the seamless flow of liquids and gases worldwide, driving progress and prosperity,” explains a recent report by the logistics experts at the Deccan Transcon Group. “As the world continues to rely on ISO tanks for the transportation of essential goods, addressing these challenges remains essential to ensuring the safety of both cargo and the environment.”

Evidently, there is no simple way to deliver industrial chemicals and raw materials. Even if using a well-understood and uniformly accepted delivery vehicle such as an ISO tank container, issues may arise. However, the efficient and safe movement of industrial chemical products must be maintained if costs are to be kept low.

Understanding the issues surrounding the use of ISO tank containers is an important part of working in the chemical industry, be it as a raw material supplier, manufacturing end-user, or chemical industry worker. They are a key tool in the supply chain of industrial chemicals, and therefore a key part of the interconnected, global economy.

Photo credit: Wikimedia, Wallpaperflare, Wikimedia, Jason Goh from Pixabay, & Wikimedia