High on the list of products restricted and strictly controlled are chemicals, as they are publicly perceived to be substances that are likely to be toxic to the environment and to human life.

“Some well-known examples of restricted substances are lead, BPAs, PFAs, phthalates, and more,” explains Renaud Anjoran, a supply chain management expert who specialises in import/export from Asia to Europe. “For example, they cause cancer, reproductive damage, and other diseases, and/or they do not degrade once in the environment (including in our bodies).”

It is therefore essential for every chemical supplier, importer, trader, or manufacturer to take great care in ensuring compliance with EU legislation.

Failing to adhere to these regulations will make a product non-compliant, and as such may be withdrawn from the market, have its import blocked at the border, or may be recalled from consumers (even after the final sale). Products may then have to be exported, reworked, or destroyed.

Most Common Failings for Importers

“The most common recalls on products found in our study, were for non-compliance with REACH,” explains quality control specialist Fredrik Grönkvist of Compliancegate.com, “but in most cases, the importers were required to stop marketing and selling the products rather than the products being recalled from consumers.”

Examples of non-compliance include jewellery with a high level of cadmium (a cancer-causing metal often used as an alloy) and gloves which contain a plastic coating with a high level of phthalates (a common plasticizer used to make plastics softer to touch, but also responsible for reproductive damage).

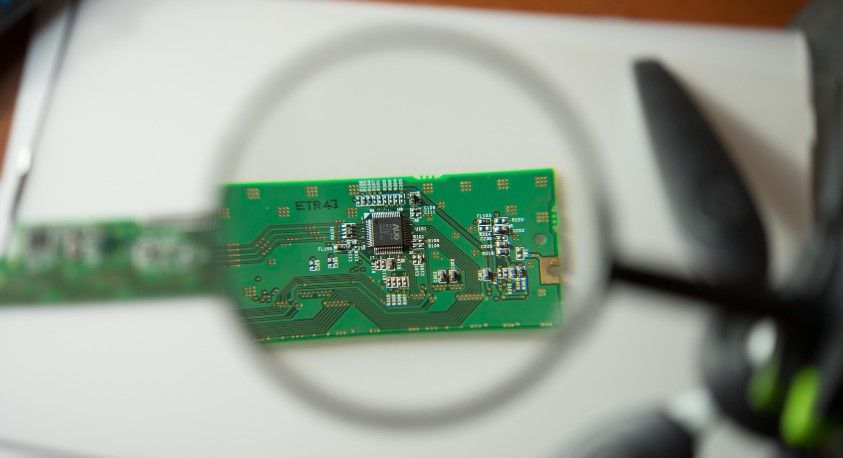

Grönkvist stated that the products which are most frequently pulled up as being non-compliant of EU chemical regulations are jewellery and home textiles. However, domestic electrical appliances are regularly held up at the border as they fail to meet standards for RoHS and POPS regulations.

To learn more about how to import products or chemical raw materials into Europe, read: EU Chemical Rules: The Four Most Significant Directives

“The non-compliances found are probably because market surveillance authorities focus on the regulation/s relevant to specific product categories,” says Grönkvist. “For example, they know that electronics are regulated by RoHS, so they may open up electronics they deem risky and check the welding for lead. If lead is found, the product likely fails RoHS compliance. They may also know that, in their area at least, they’ve been seeing problems with a specific type of product more frequently and are therefore likely to pay them special attention.”

That said, very few products fail to meet standards, as most chemical suppliers or manufacturers are wise enough to check the relevant documentation before importing begins. For this reason, in the past 12 months, only 14 substances have been recalled from the EU market due to chemical regulatory breaches. Most of these were due to products containing phthalates, especially in toys and bags.

Top Tips for Importers to Avoid EU Chemical Regulation Breaches.

1. Request compliance documentation from potential suppliers.

Ask the supplier to provide evidence of compliance, such as pre-existing test results for past items they've sold or produced.

2. Obtain or draw up a bill of materials.

Requesting or creating a list of all the items (and their composite parts/raw materials) will allow for a clearer risk assessment and analysis of what directives and regulations need to be checked.

3. Contract conditions.

Make sure that both the supplier and the purchaser understand who will be responsible for ensuring regulatory compliance. Costs for lab testing can be shared, but it is wise to withhold final payments until products have the correct paperwork to pass import controls.

4. Avoid assumptions.

Do not presume that a supplier will produce your items in accordance with those regulations even if they have a solid track record of doing so. Be absolutely clear with the manufacturer and ensure that it is written in the contract in an enforceable way that compliance is part of the deal.

To put this advice in a nutshell, importers of chemicals or manufactured products containing chemicals need to stay well informed of the rules as well as maintain excellent communication with those involved in the import process.

The chemical industry is one of the most restricted parts of the economy. A vital sector for business, but also one that is filled with a minefield of safety requirements and policy. Staying on top of the ever-changing rules is never easy, however it is an essential part of importing, exporting, and manufacturing.

While failing to do so rarely results in legal action against companies or individuals, the delays, returns, recalls, and possible product destruction are all expensive outcomes. Clearly the message to be learnt is adhere to the rules or suffer the consequences. You have been warned!

Photo credit: Jannoon028 on Freepik, Tawatchai07, Freepik, & Wirestock