By finding a new way to attach chemical additives to polyvinyl chloride, material scientists have discovered a less brittle, more durable form of PVC. Moreover, the new polymer has sturdier bonds, reducing the amount of microplastic particles that it leaches into the environment.

PVC, or polyvinyl chloride, is a widely used thermoplastic polymer that has become an integral part of modern life. Derived from the simple combination of chlorine (obtained from salt) and ethylene (a petroleum-based product), PVC is a remarkably versatile material with a diverse range of applications.

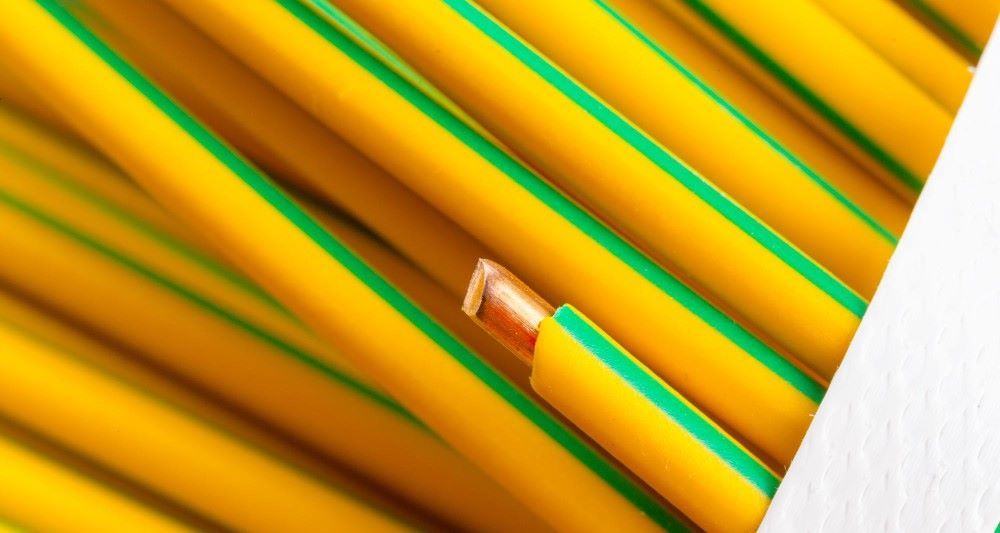

Its unique molecular structure, consisting of long chains of carbon atoms with attached chlorine atoms, gives PVC exceptional durability, strength, and resistance to weathering, chemicals, and fire. This makes it an ideal choice for a multitude of products, from sturdy plumbing pipes, bank cards, and resilient flooring to flexible electrical cable coatings and durable packaging materials. For this reason, it is the third most manufactured polymer in the world.

Conventionally, the long polymer chains which give PVC its strength are brittle and heat-sensitive, so manufacturers need to stabilise its qualities with other chemical additives or plasticizers. Over time, these chemicals breakdown and are released as microplastic pollutants. But now a new production method could avoid this environmental damage.

“Instead of mixing in those chemicals,” explains Ohio State University’s Associate Prof. Christo Sevov, the study’s principal investigator, “our method involves chemically bonding the plasticizer compound directly to PVC by grafting them onto the backbone of the polymer.”

By changing PVC molecules in this way, the polymer gains properties such as added strength, resilience, and durability, in a process which is highly tuneable.

“This is the first step in controllably modifying PVC to give it properties you're interested in, whether it's hard, stretchy or soft,” observes Sevov. “This is really one of the few examples that we have where there's this much control over changing the properties of PVC.”

The study has now been published in the journal Chem, which fully describes, “… the electrocatalytic functionalization of PVC to covalently graft plasticizing additives directly onto the polymer backbone.” The result is a process, “… to create chemically and leach-resistant PVC materials by directly electrolyzing mixtures of consumer PVC products.”

Most significantly, the process is highly suitable for use at an industrial level, with Sevov stating that, “There's no better way to do this on the scale you would need for commercial PVC modification because it is an immense process.”

Like all novel approaches, the discovery was not straightforward, with the researchers running into numerous problems. As the online journal Phys.org outlines, “… synthetic polymer modifications often fail because the reactions were originally developed for small-molecule analogs, not big-molecule analogs such as pure PVC. To solve this, researchers optimized the catalyst they used in their process, and through trial and error, were able to overcome the issues that arise when editing big molecules.”

“You can potentially reuse the material many, many more times before it really begins to fall apart, improving its lifetime and reusability,” notes Sevov.

However, it is the news of a process which manufactures durable PVC with a reduction in microplastics that is gripping many in the plastics industry. With plastics pollution a major global issue and the consequences of microplastics causing unknown health risks in every living creature on the planet, finding a solution to limit their spread is a top priority.

“Many chemists are shifting their efforts to studying big molecules and developing new chemistries for upcycling, recycling and modifying well-known polymers,” adds Sevov. Before concluding that, “There's still a lot to play around with before we solve the microplastic situation, though now we've laid the groundwork for how to do it.”

Photo credit: Freepik, Freepik, & Fabricasimf