With more than 1,900 chemical products used in the production of clothing, chemical companies are already heavily involved in the fashion industry. From the manufacture of dyes and cloth cleaning products, to synthetic fibre production and waterproofing chemicals, the chemical industry is a key product and service provider for the garment industry. But now, a growing sector of chemical demand is for those used in the recycling of clothes.

With this new trend in mind, here is an overview of the challenges, solutions, and the future facing the recycled clothing industry.

The Challenges Facing the Recycled Clothing Industry

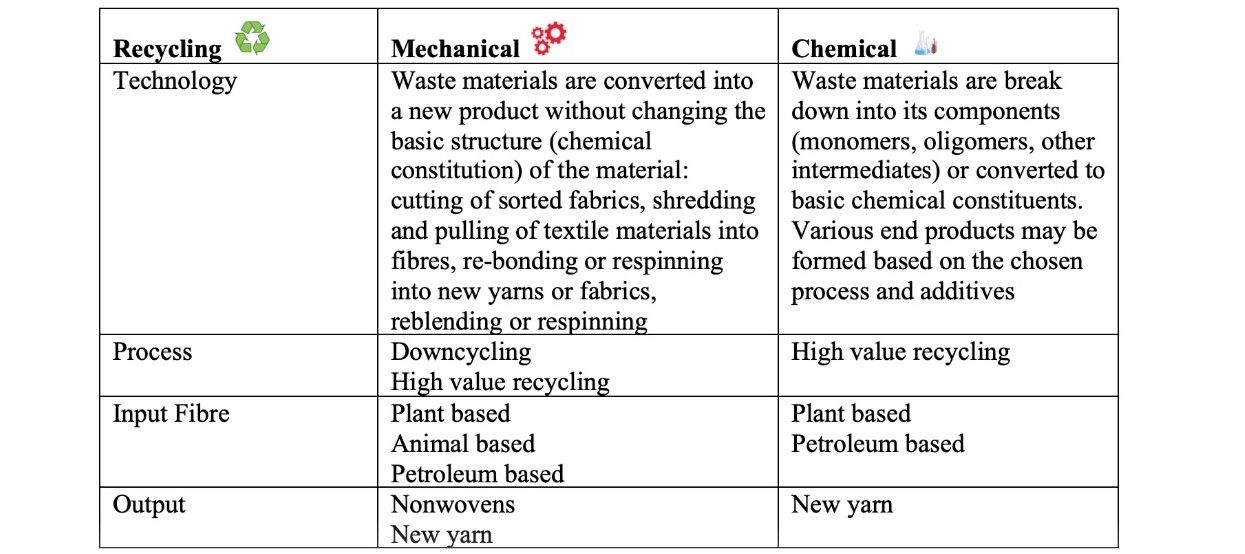

When understanding how clothing is recycled, it is important to establish the two main approaches: mechanical and chemical. Kate Goldsworthy, a senior research fellow at Textiles Environment Design, highlighted the differences in a recent interview with the Guardian, “The key differentiation is between ‘mechanical fibre recycling’, which will degrade with each recycling (down-cycling) and ‘chemical fibre recycling’ which in some cases can produce fibres of equal quality to virgin ones.”

The problem with mechanical recycling is that the fibres are damaged in the process, and so cannot easily be reused as clothing. This is in large part because shredding shortens fibre length.

As Hanna de la Motte, a textile recycling chemist at RISE Research Institutes of Sweden in Göteborg, observes, “You cannot take a well-used cotton T-shirt, mechanically tear it apart and then make the cotton fibres into a new cotton T-shirt, because they have lost so much fibre quality that the T-shirt will not be of high enough quality to fit into the market.”

One solution to this problem is to mechanically mix the shorter recycled fibres with longer virgin fibres to form a new material. However, this is not always economically viable and still produces an item of clothing that is not inside the circular economy.

The result is that most items of clothing are down-cycled; turned into insulation material, industrial cleaning cloths, mattresses, and sofa stuffing. Today, less than 1% of garments are recycled into new garments.

Worse still, the Ellen MacArthur Foundation estimates that globally 73% of discarded clothing is either incinerated or ends up in landfill.

The clothing industry creates a large amount of ecological damage. For example, according to a report by the Royal Chemical Society the use of dyes can use as much as 150 litres of water per kilogram of fabric. The chemical industry is also responsible for the production of synthetic fibres such as nylon and polyester which are made from non-sustainable raw materials.

These non-organic materials also play a major role in pollution, with data compiled by the European Union parliament finding that, “… one load of laundry of polyester clothes (also nylon and acrylic) can discharge 700,000 microplastic fibres, which release toxins into the environment and can end up in the human food chain.”

While the use of recycled polymers is increasing (market share rose from 8 % in 2007 to 14 % in 2017), the majority of the reclaimed raw material was from plastic bottles, not recycled clothing.

There is clearly an environmental impact from the amount of clothes that we wear. As the Guardian newspaper reports, “Textile production, especially those made from synthetic polymers, uses a huge amount of non-renewable natural resources: 98 million tonnes of oil globally each year.” Adding that, “The fashion industry also uses vast quantities of water and is a significant contributor to the climate emergency, with greenhouse emissions on the same order of magnitude as international flights and maritime shipping combined.”

With So Much Raw Material being Wasted, Why Isn’t More Being Done to Recycle Clothing?

There are certainly advantages for greater chemical recycling of clothes. As Tasha Lewis, an associate professor in the Department of Fiber Science and Apparel Design at Cornell University, explains, “This [chemical recycling] should reduce demand for pesticides, petroleum and water - to name a few potential environmental benefits. There may also be new job creation [and] businesses around the collection, sorting and processing of post-consumer textile waste for large-scale recycling.”

However, most of these advantages are not yet being fully utilized. “I think the collection and sorting processes for the post-consumer textile waste needed to drive these technologies at scale are still lagging behind,” says Lewis. Progress is also required from clothing producers to better label the materials used so that they can be easily identified. “In my research, we had to do a bit of detective work to find out a particular fiber content for a garment since many used garments are missing content labels. This could also slow down processing.”

With these problems, it is easy to see why so little used clothing is recycled.

However, where there is a will, and a profit to be made, there is a way.

To learn about how the chemical industry is meeting these challenges, read: The Chemical Recycling of Clothes looks to be Big Business. Part 2; The Solutions

Photo credit: Aboutbiosynthetics, Designforlongevity, Wornagain, Mistrafuturefashion, BBC, JapanToday, Qz, Globalrecycling, Spectralengines, Medium, Theretailbulletin, Newsweek, Infinited Fiber, & Womensvoices, Unsplash