For years, a debate has been raging over whether Bisphenol A is dangerous or safe.

But this argument may now become irrelevant as a team of researchers has created a bio-polycarbonate that is as strong and tough as fossil fuel plastics, yet it uses glucose as its main raw material.

The Love & Not-So-Love Affair with Bisphenol A

When first discovered back in the 1950s, no one knew that Bisphenol A (or BPA) would be the cause of some much trouble.

It was originally used in the first epoxy resins, but General Electric and Bayer soon learnt that the molecules could link together with a small connector compound to form the hard, shiny plastic called polycarbonate.

This led to today’s polymer industry using Bisphenol A as a common building block for the manufacture of numerous resins and different kinds of plastic.

However, health concerns have grown over the effect this raw material may have on the health of both wildlife and people.

This is because, BPA is an endocrine disrupting compound; a chemical that once inside the body can act like a hormone, potentially disrupting the function of natural hormones.

The fears are based on a wave of studies that have analysed the effects of BPA, finding that it can negatively impact the reproductive, developmental, and metabolic welfare of many different animals, including zebrafish, rhesus monkeys, nematodes, mice, and significantly humans.

Despite this, most governments continue to allow its production and use, citing other researchers who found BPA to be safe, although some have begun to restrict its application. Most notably, the EU banned the use of BPA in baby’s bottles in 2011, with plans for stopping its use in thermal paper as early as next year. While in Korea it is banned from milk bottles and cosmetics.

This has put the issue of finding a replacement firmly in the sights of researchers.

And now a breakthrough has been made, as a team from the Korea Research Institute of Chemical Technology (KRICT) has created a bio-polycarbonate made largely from glucose. Unlike earlier bio-polymers, the team claim that this new bio-polycarbonate has the strength and durability to match its petrochemical counterpart, paving the way for commercialization.

Up until today the only company to successfully commercialize a bio-polycarbonate product has been the Japanese corporation Mitsubishi Chemical.

This latest discovery was made by Dr Jeyoung Park, Dr Dongyeop Oh, and Dr Sung Yeon Hwang of the Research Center for Bio-based Chemistry at KRICT, who were able to develop an alternative commercially viable bio-polycarbonate using the plant-based components of isosorbide and nanocellulose.

The biggest challenge in creating any new bio-polymer is making production cheap enough, but at the same time the product must be strong enough to compete in the market with its fossil fuel counterparts.

For this reason, the KRICT team looked at isosorbide, an eco-friendly compound derived from glucose known not only for its strong mechanics, but also because its unique molecular structure provides ‘good optical and UV-resistive properties’.

As the scientific journal Phys.org, explains, “The research team applied the principle of ‘like dissolves like’ where similar compounds mix together better. Isosorbide well mixed together with nanocellulose as a bio-derived reinforcing agent because both substances are hydrophilic and have a similar structure. Then, the polymerization process of the nanocomposite plastic was carried out. The well dispersed nanocellulose acted like metal rebar in concrete and thus maximized the strength of the bio-plastic.”

The result was a strong bio-polycarbonate produced relatively cheaply, and which could also be transparent, a failing in many previous bio-plastic products.

Bio-Polycarbonate Strength

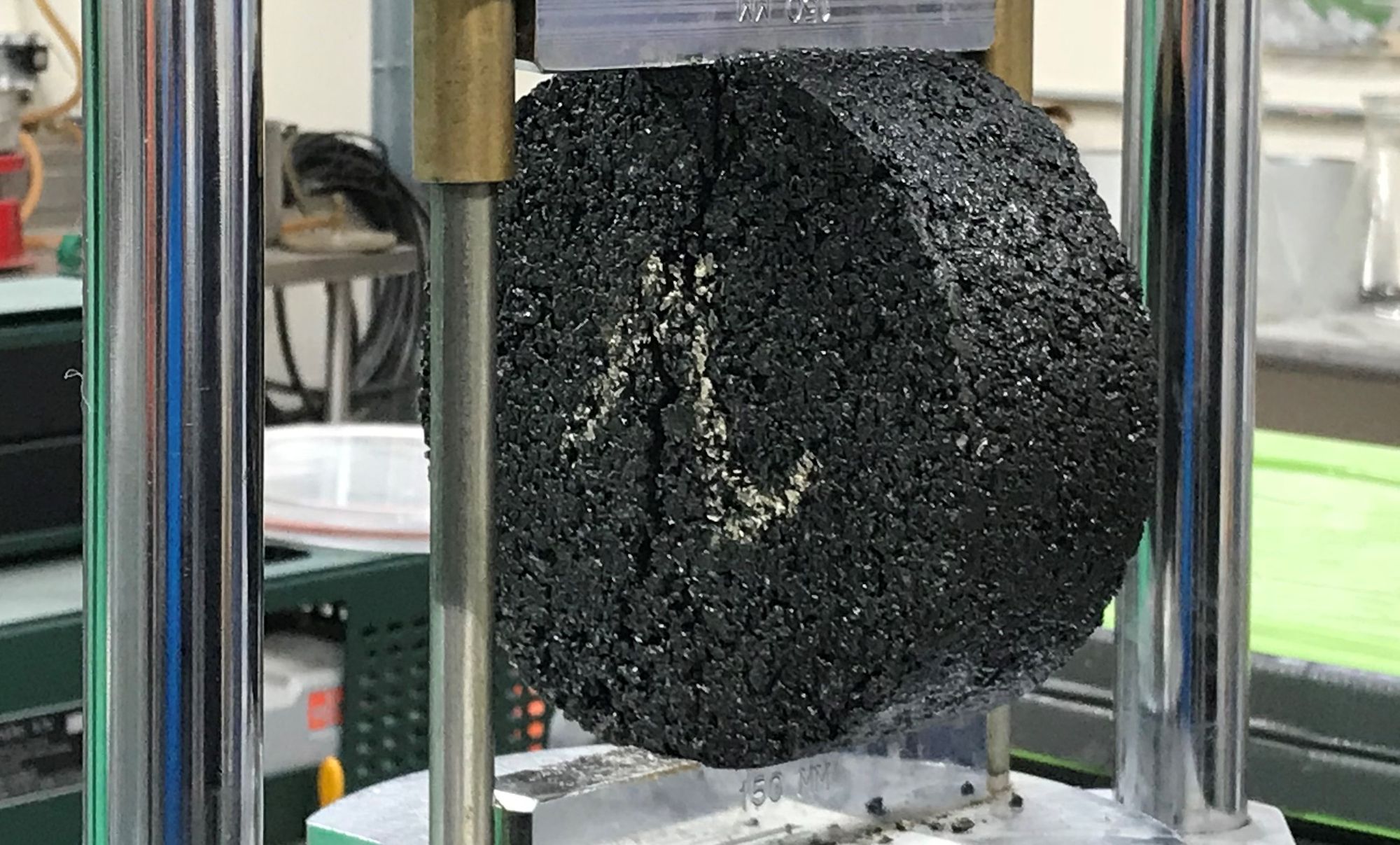

In fact, tests showed that this latest bio-polymer was stronger than standard polycarbonates, both petrochemical and bio-based. Fossil fuel polycarbonates typically have a tensile strength of between 55 and 75 MPa, while the Mitsubishi Chemical Corporation’s bio-plastic measures 64 to 79 MPa. The KRIST bio- polycarbonate measured 93 MPa.

“We wanted to break the stereotype that bio-plastic has inferior mechanical properties and is expensive,” says Dr Park. “Through the synergistic interplay between the plant-based ingredients, we were able to develop a bio-plastic that is superior to petroleum plastic.”

Bio-Polycarbonate Transparency

In addition to its strength, the new polycarbonate is also highly transparent, with a light transmittance measurement of 93%. As the scientific journal EurekaAlert explains, “This is due to the suppressed crystallinity through the dispersed nanocellulose and the result is very superior to commercially available petroleum polycarbonate. This is outstanding because most nanocomposites have a reduced transparency because nonuniform aggregates scatter light. In addition, there is no risk of discoloration even after extended exposure to ultraviolet rays since there are no benzene ring in bio-polycarbonate, unlike petroleum polycarbonate.”

This opens up the possibility of using the bio-polycarbonate in many other industrial applications, such as headlights, transparent highway noise barriers, sunroofs, and in the casing of electronic devices.

Bio-Polycarbonate Low Toxicity

Furthermore, the bio-polycarbonate has also shown to be much safer than petrochemical polymers, making it possible to use in products where BPA is not.

“A low toxicity result was obtained from the in vivo inflammatory testing using a rat.” Says Dr Dongyeop Oh. “The toxicity level is safe for infants and children to put in their mouth, which means that the materials can be used for medical purposes in such things as implants and artificial bones, as well as toys, milk bottles, and baby strollers.”

Test results from injecting the polymer into rats to test for inflammation gave the bio-product a toxicity level of 1, on a scale of 0 – 5 where the lowest toxicity value is 0. A result that will allay the concerns that many have over the toxic nature of many household plastics.

“Fear of plastics is growing because of the issues like plastic waste and chemophobia,” says Dr Hwang Sung Yeon, “but plastics have become an essential part of everyday life so we will develop bio-plastics that people can use without fear.”

The polycarbonate market is huge, with current global production of about 5 million tonnes per year. At present, the bio-polycarbonate share of this is monopolized by Mitsubishi, which produces only 20,000 tonnes annually.

However, with growing pressure from consumers and governments to find safer products that meet climate change and emissions targets, the entry to the market of a novel bio-polycarbonate is exciting news. Given that the new bio-plastic is in many ways superior to conventional polycarbonates it is perhaps just a matter of time before bio-polymer products break petrochemical dominance in the plastics industry.

Photo credit: Undark, Phys.org, SurfaceTech, Saferchemicals, LinkedIn, & Coperion