Researchers from MIT have discovered a way to synthesize polymers that break down more easily and more quickly. While originally devised as a less toxic way to deliver drugs to patients, the process is also adaptable for making plastic that disintegrates faster; helping to solve the problem of plastic waste.

The study was based on a chemical reaction called ring-opening metathesis polymerization (ROMP) which has long been known as a way to construct new polymers. The resulting plastics are high-quality, and are commonly used in imaging agents, nanofabrication, high-performance resins, and in capsules for drug delivery. However, polymers created using this method do not easily degrade in ambient conditions, such as sea water or inside the body.

As the study, which has been published in the journal Nature Chemistry, explains, “[ROMP] is a powerful approach for the synthesis of macromolecules with diverse compositions and complex architectures. Nevertheless, a fundamental limitation of polymers prepared by this strategy is their lack of facile degradability, limiting their utility in a range of applications.”

By adding a novel type of building block to the backbone of these polymers, the team has created a plastic that degrades faster in mild conditions.

“We believe that this is the first general way to produce ROMP polymers with facile degradability under biologically relevant conditions,” says Jeremiah Johnson, the study’s senior author and an associate professor of chemistry at MIT. “The nice part is that it works using the standard ROMP workflow; you just need to sprinkle in the new monomer, making it very convenient.”

Because it is made from different chemical bonds, the new monomer breaks down much more easily with weak acids, bases, and commonplace ions such as fluoride.

The process of creating this new polymer was outlined in an MIT press release, which stated that, “The most common building blocks of ROMP-generated polymers are molecules called norbornenes, which contain a ring structure that can be easily opened up and strung together to form polymers. Molecules such as drugs or imaging agents can be added to norbornenes before the polymerization occurs.”

“It's a very robust and powerful polymerization reaction,” Johnson highlights. “But one of the big downsides is that the backbone of the polymers produced entirely consists of carbon-carbon bonds, and as a result, the polymers are not readily degradable. That's always been something we've kept in the backs of our minds when thinking about making polymers for the biomaterials space.”

To tackle this problem, the team looked at developing smaller polymers, often measuring at little as 10 nanometres in diameter [0.0001 mm]. Due to their small size, these polymers could be cleared from the body more easily, reducing toxicity.

While other chemists have tried to make polymers degradable by using building blocks other than norbornenes, the results were usually substandard, as the monomers wouldn’t polymerize effectively. They also had difficulty attaching pharmaceutical chemicals to them or they would only degrade in extreme conditions.

“We prefer to continue to use norbornene as the molecule that enables us to polymerize these complex monomers,” Johnson says. “The dream has been to identify another type of monomer and add it as a co-monomer into a polymerization that already uses norbornene.”

The breakthrough began when Peyton Shieh, a postdoc researcher at MIT and a co-author on the study, was searching for new polymers that would be able to trigger drug release. In doing so, he synthesized a ring-containing molecule that was similar to norbornene but contained an unusual oxygen-silicon-oxygen bond. Unlike standard monomer molecules with carbon-carbon bonds, this ring (called a silyl ether) could be opened up and polymerized with a ROMP reaction. Adding it to a polymer backbone created a plastic product based on an oxygen-silicon-oxygen bond that was much easier and quicker to degrade.

As the scientific journal Phys.org reports, “The researchers found that by simply adding the silyl-ether monomer in a 1:1 ratio with norbornene monomers, they could create similar polymer structures to what they have previously made, with the new monomer incorporated fairly uniformly throughout the backbone. But now, when exposed to a slightly acidic pH, around 6.5, the polymer chain begins to break apart.”

“It's quite simple,” says Johnson. “It's a monomer we can add to widely used polymers to make them degradable. But as simple as that is, examples of such an approach are surprisingly rare.”

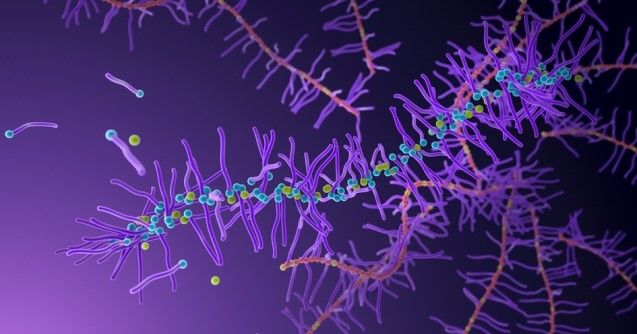

The MIT team have now synthesized a variety of polymers with many different forms, including linear polymers, star-shaped polymers, and bottlebrush polymers, all useable for delivering cancer drugs or for carrying imaging agents suitable with magnetic resonance imaging (MRI) or other types of imaging.

Tests to compare the new polymer’s toxicity against standard drug delivery systems have already produced positive results. As the MIT press release outlines, “In tests in mice, the researchers found that during the first week or two, the degradable polymers showed the same distribution through the body as the original polymers, but they began to break down soon after that. After six weeks, the concentrations of the new polymers in the body were between three and 10 times less than the concentrations of the original polymers, depending on the exact chemical composition of the silyl-ether monomers that the researchers used.”

Ultimately showing that adding this monomer to polymers for drug delivery or imaging would help the body to break them down and expel them more quickly. This creates a less toxic system which could be further developed to aid other medical procedures.

As Johnson states, “We are excited about the prospect of using this technology to precisely tune the breakdown of ROMP-based polymers in biological tissues, which we believe could be leveraged to control biodistribution, drug release kinetics, and many other features.”

With this in mind, the team are cooperating with science specialists at Millipore-Sigmato produce the monomer commercially. However, beyond its applications in the pharmaceutical industry, the discovery also holds great potential in other sectors.

Already the researchers have begun attaching the new monomers to industrial resins, such as adhesives or plastics to make them more easily degradable.

Given the relatively ease with which the building blocks were attached to the polymer backbone for a pharmaceutical product, the team are confident that the process will be economically viable for more industrial products.

If this goes to plan, then the new process may not only make safer drugs, but may also provide an affordable route to reducing the impact of plastic waste in waterways, oceans, and landfill.

Photo credit: Sciencetimes, MIT, Phys.org, Sciencenewsforstudents, MIT, IBMM, & Technologygateway