A new foam-like substance could make everyone safer by improving impact protection in helmets, car parts, body armour, and maybe even bulletproof vests. And as the material is reusable, it could even help save the planet.

The new design was created by a research team who saw how often modern car bumper and helmet technology failed at high speeds. They also noticed how once these materials have been involved in an impact, they are no longer effective and must be thrown away. Car drivers who have been involved in even a minor collision will know the shortcomings that the composites used in the ‘crumple zone’ brings.

To solve the problem, the John Hopkins scientists experimented with high energy-absorbing liquid crystal elastomers (LCEs), which have previously found use in robotics and electronic machinery.

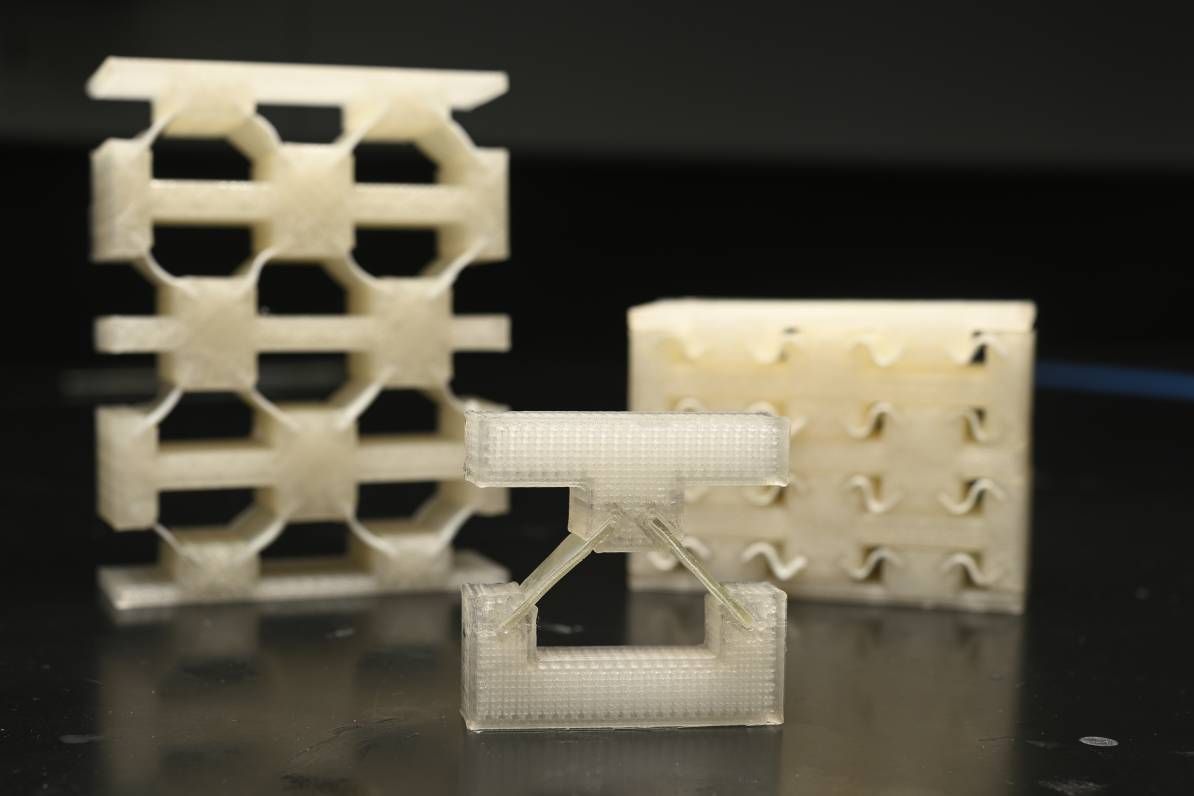

This resulted in the development of a complex liquid crystal structure which when combined with a lightweight elastomer makes an ideal material for use in manufacturing body armour. Most importantly, the new technology provides a raw material which is reusable while still providing high impact strength with low weight - a major breakthrough in body armour development.

As the study’s senior author Asst Prof. Sung Hoon Kang, notes, “We are excited about our findings on the extreme energy absorption capability of the new material.”

This new technology a significant advance on current impact-absorbing materials which are made with a material that dissipates energy through inelastic mechanisms. For example, bulletproof vests use composites which deform, while protective visors fracture or fragment upon impact. The result is that they are single use materials, which are permanently damaged and not suitable for repeated use.

By developing what the researchers call ‘elastic buckling instabilities’ – described as an atomic-level bounce – the researchers have made a more environmentally friendly protective material.

As the website Popular Mechanics explains, “Think of a big spring, which buckles under pressure, but then pushes right back into shape. The idea of buckling needn’t be a one-way deformation that permanently distorts the material. It can store up energy that is re-released in order to ‘bounce’ the material back to its true form.”

“This structural energy trapping mechanism is scalable and reversible,” the researchers add, “which makes the architected material reusable.”

The university website further explains how protective the new structure could be. Stating that, “During experiments to test the material's ability to withstand impact, it held up against strikes from objects weighing about four to 15 pounds [1.8 to 6.8kg], coming at speeds of up to about 22 miles per hour [35 kmh]. The tests were limited to 22 miles per hour due to limits of the testing machines, but the team is confident the padding could safely absorb even greater impacts.”

“The material offers more protection from a wide range of impacts,” Sung says. “But being lighter could reduce fuel consumption and the environmental impact of vehicles while being more comfortable for protective gear wearers.”

This latest research is an extension of the work of other material scientists who are looking into improving body armour and high-impact resistance substances which have a lower environmental impact. This include not only recyclable materials but also natural substances, such as clays and fabrics, including a woven hemp-related called kenaf, which can be enhanced with Kevlar and/or aluminium.

Other researchers and manufacturers are experimenting with nanotechnology and ways to apply nanomaterial coatings and super-strong graphene to polymers as a protective barrier.

To learn more about this topic, read: A Stronger, Lighter Polymer which May Revolutionise Body Armour.

Quotations and photos accredited to: John Hopkins University

Additional Photo credits: Viridiana Ortiz on pexels, Jesse Zheng, & Hassan OUAJBIR