If humankind is to truly reduce its impact on climate by lowering carbon emissions, then everyone must rethink the raw materials being used.

The challenge lies in the fact that so much of the modern world depends on fossil fuels. Even the manufacture of basic household cleaning agents is based on processing crude oil feedstocks to make petrochemical products such as linear alkylbenzene sulfonate or synthetic alcohol ethoxylates.

These chemical products are surfactants, and are used in cleaning products to breakdown fats, oils, and grease.

Early attempts for making these chemicals with lower carbon emissions still required petrochemical inputs blended with natural feedstocks. Further research allowed for the manufacture of fully bio-based surfactants but were based on natural oils sourced from tropical climates. The shipping distances from feedstock source to market added a large carbon footprint, while many of the production methods used hazardous raw materials and procedures.

However, a completely new process has been developed which avoids these pitfalls.

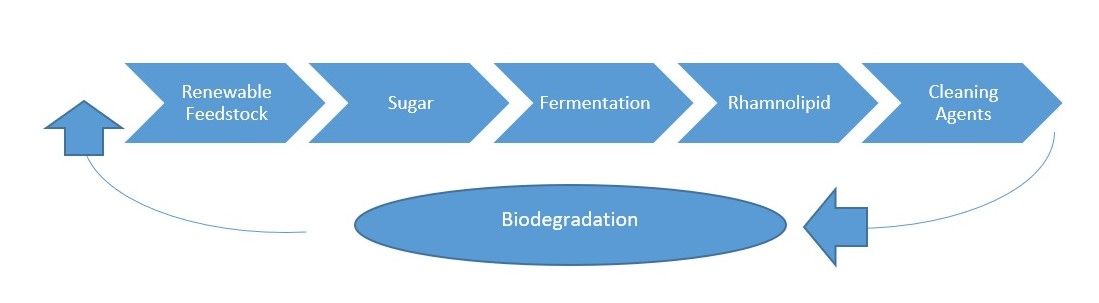

This new generation of surfactants are called rhamnolipids or sophorolipids. They can be produced with no petrochemical inputs but are instead based on sugar as a primary feedstock.

The new process is also viable at an industrial scale, as the producers, Evonik, explain, “[Rhamnolipids can be produced] from locally sourced (EU) bio-based raw materials without the use of tropical oils. They are produced by a safer, mild, and low energy fermentation process … [and can] perform in any condition - independent from water quality.”

The new facility has been built by Evonik in the town of Slovenská Ľupča in Slovakia, where the company will manufacture the new generation of cleaning agents under the trademarked names of RHEANCE® One for personal care applications and REWOFERM® RL 100 for cleaning solutions.

“With this investment we are pioneering a new market,” says Johann-Caspar Gammelin, President of the Nutrition & Care division at Evonik, “as we believe that this will transform the way the world cleans.”

According to Evonik, the new biosurfactants, “… not only remove grease and dirt but are also eco-friendly and gentle on the skin. They are 100 percent biodegradable and therefore enable circular economy. They come with the lowest aquatic toxic profile available on the surfactant market and are safe for oceanic life.” Adding that the new product, “… will convince formulators and consumers that environmental compatibility and cleaning power need not be contradictory.”

The manufacturers state that REWOFERM® Biosurfactants:

· Are suitable for both household and industrial purposes

· Are the most environmentally compatible surfactants on the market

· Satisfy the requirements of OECD 301 F and EN ISO 11734 for rapid biodegradability under both aerobic and anaerobic conditions

· Have exceptional foam-forming properties make them suitable for use in household cleaners and personal care products like shampoos and micellar waters

· Score an exceptional 100% on the Renewable Carbon Index (RCI)

· Have a pleasant taste which enables their use in oral care products such as toothpaste without strong taste-masking components

· Perform significantly better than all conventional, reference surfactant products in water toxicity tests (OECD 211 and 202)

“Rhamnolipids are an important part of our Clean Future initiative which has set the goal to exclude fossil carbon in all cleaning products by 2030,” says Peter Dekkers, Executive Vice President Middle Europe, Unilever. “We want to make sustainability easy for everyone that uses our products. The partnership with Evonik helps move our brands away from fossil fuels without compromising on performance or affordability.”

The Evonik Fermas site in Slovakia was established more than 25 years ago, during which time it has become a strategic location and biotech hub for industrial chemical development.

A key part of this triple-digit million-Euro investment is the construction of the world’s first industrial-scale facility for manufacturing high-quality, sustainable biosurfactants on a commercial scale.

As Gammelin concludes, “This is a game changer for cleaning and personal care products.”

Photo credit: Karolina Grabowska on Pexels, Vinatge Blue on Pixabay, & Vicki Hamilton