The route to replacing petrochemicals and fossil fuels with more sustainable chemicals and fuels sourced from biomass has been a long sought for goal. Like the frozen North-West passage or the lost city of Eldorado, finding a process to chemically breakdown the lignin and cellulose in plant matter to release the energy and chemical raw materials inside has been a seemingly unsolvable riddle.

The problem lies in the innate defences that exist in plant cell walls, making current biofuel and biochemical processes costly in terms of energy, time, and money.

However, a combined team from the University of California (Riverside), Oak Ridge National Laboratory, and the University of Central Florida have discovered a path to breakdown the lignin that acts as a natural shield for the energy-rich and chemically useful cellulose.

Lignin is a complex polymer that is largely resistant to both biological and chemical attack. Meaning that, previous studies that focused on extracting the desired raw materials from cellulose have always had limited success due to the challenges presented by lignin.

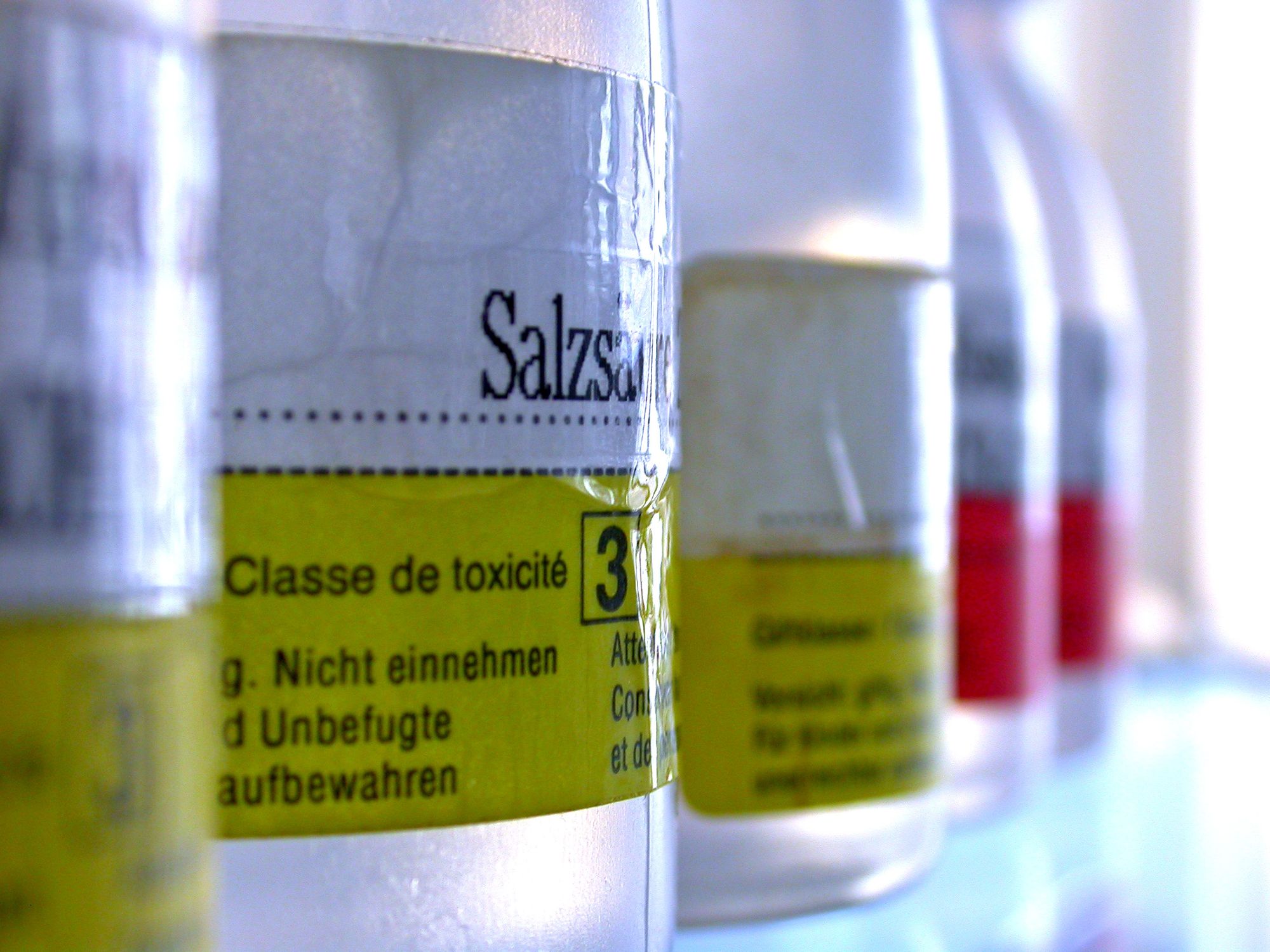

As the University of California (Riverside) website, explains, “In the past, different specialized chemicals and pre-treatment methods have been used to improve enzyme access to cellulose but were ineffective at removing lignin. The use of strong acids, ionic liquids, ammonia, and sulfite treatments have somewhat improved the digestibility of cellulose, but these methods also leave lignin behind, making cellulose expensive to recover. Other methods have applied co-solvents such as ethanol and acetone solvate to remove lignin, but they require very high reaction temperatures that also cause the remaining sugars to degrade.”

By combining a ‘lignin-first’ approach with supercomputing power and highly specialized co-solvents (substances added to a primary solvent to make it more effective) the team, led by Abhishek S. Patri, a doctoral student in chemical and environmental engineering, and Charles Cai, an assistant research engineer at UC Riverside, believe they have made a breakthrough in solvating the lignin and in making biochemicals a more economically viable option.

The supercomputing analysis, was based at Oak Ridge National Laboratory’s Center of Molecular Biophysics, where the researchers, led by Jeremy Smith, constructed, “… a 1.5 million atom molecular simulation to reveal how the co-solvent pair consisting of tetrahydrofuran, or THF, and water are particularly effective at altering the interactions between lignin and cellulose, helping to drive multiple key mechanisms responsible for breaking down biomass.”

The combination of water and THF causes lignin to break away from both the cellulose and itself, expanding into a ‘random coil’. Once detached, dilute acid can be added, causing further chemical breakdown to the lignin, leaving it more accessible to depolymerization. The final steps include converting the lignin into a soluble form before transporting it out of the cell wall, all of which can be performed with milder treatments that keep the chemical quality intact.

Powerful lasers and nano-infrared imaging was then used at the University of Central Florida to, “optically track lignin’s rearrangement and removal from the cell wall of micron-thick slices of hardwood.” While a further team from Oak Ridge National Laboratory proved that the lignin extracted via the THF co-solvent process was “significantly depolymerized and contained fewer unwanted reactions than lignin produced from other acidic pre-treatment methods.”

This process removes almost all traces of lignin, easily exposing the cellulose for processing with enzymes, achieving complete hydrolysis to glucose sugars if desired.

The ability of this new co-solvent process to access the chemical building blocks contained in both lignin and cellulose could have a far-reaching impact on the biofuel and biochemical industries. While the value of these chemical raw materials has long been known and are used in the production of, among other things, rayon for clothes, nitrocellulose for explosives, and cellulose acetate for films, the cost effectiveness of extracting these chemical ingredients has always been questionable.

By finding a clear path towards separating the defensive lignin from the energy-rich cellulose the team hope to attract further study into the power of co-solvents, especially in the biochemical industry. Additionally, the researchers are happy to have helped the chemicals industry take a further step towards participation in the circular economy.

Photo credit: University of California (Riverside), RSC, Amazonaws, & Storaenso