Finding suitable ingredients to make high-quality concrete is about to become a lot easier, as researchers have found that waste coal ash makes an ideal raw material.

With concrete remaining the ‘go to’ material for constructing bridges and buildings, the ability to use a waste product from coal fired power stations to make structures stronger and more durable is a win-win situation. At present, tens of millions of tons of ash ends up in landfill sites every year.

As any construction worker will tell you, making concrete is not as easy as simply mixing the raw materials together. Instead, concrete is made up of an ‘aggregate’ of fine powder and coarse rock particles, which bond together with a mineral glue or ‘cementing matrix’ of cement and water.

For top-quality concrete it is important that the cement mixes thoroughly with the water and that the drying or ‘curing’ process is uniform. All the concrete must dry out at the same time.

As Yaghoob Farnam, Ph.D., an assistant professor at Drexel's College of Engineering and the study’s principle investigator explains, “This is a very important part of the process because if the concrete dries too quickly during its curing, due to added water shortage, it can form cracks and other flaws. These drying shrinkage cracks cause the surface to be susceptible to aggressive fluid ingress creating concrete durability problems such as corrosion, salt damage, or freeze-thaw damage.”

This means that often construction workers need to wait until the weather and humidity are suitable for making concrete. Additionally, they must employ a variety of techniques to ensure that the concrete cures evenly. For example, spraying the concrete with water to ensure that the outside does not dry out before the inside, submerging the concrete in water, covering the concrete with a membrane to keep it moist, or leaving the concrete to dry with pools of water on it.

As the scientific journal Phys.org reports, “All of these strategies consume time and resources and are complex enough that flaws could creep into the process. To help prevent this, in the last decade researchers have developed an internal curing concept that uses porous lightweight aggregate to aid the curing process. The aggregate can maintain a consistent level of moisture inside the concrete to help it cure evenly from the inside out.”

However, this requires the use of a premium aggregate. As the report explains, “Getting the exact amount of moisture inside concrete is difficult because the powder and aggregates form a tight cementing matrix that is difficult to penetrate once it begins drying. If the outside of the concrete dries out before the inside cures it can result in a weaker structure. As a result, contractors basically have one shot to get the ratio of liquid to solid just right, quickly and thoroughly mix it and pour the concrete before it starts drying.”

“This is a common problem in concrete,” notes Mohammad Balapour, a doctoral researcher in Farnam's lab and the paper’s lead author. “So called ‘concrete drying’ creates drying cracks and lower concrete strength and durability.”

A problem that may now be solved with the use of coal ash as an effective concrete aggregate.

“The solution we came up with involved recycling this waste product, coal ash, into a porous, lightweight aggregate with excellent performance characteristics that could be produced at a lower cost than current natural and synthetic options,” says Farnam. “This material and process would not only benefit the concrete industry by improving the quality of their products, but it could also help keep coal ash out of landfills.”

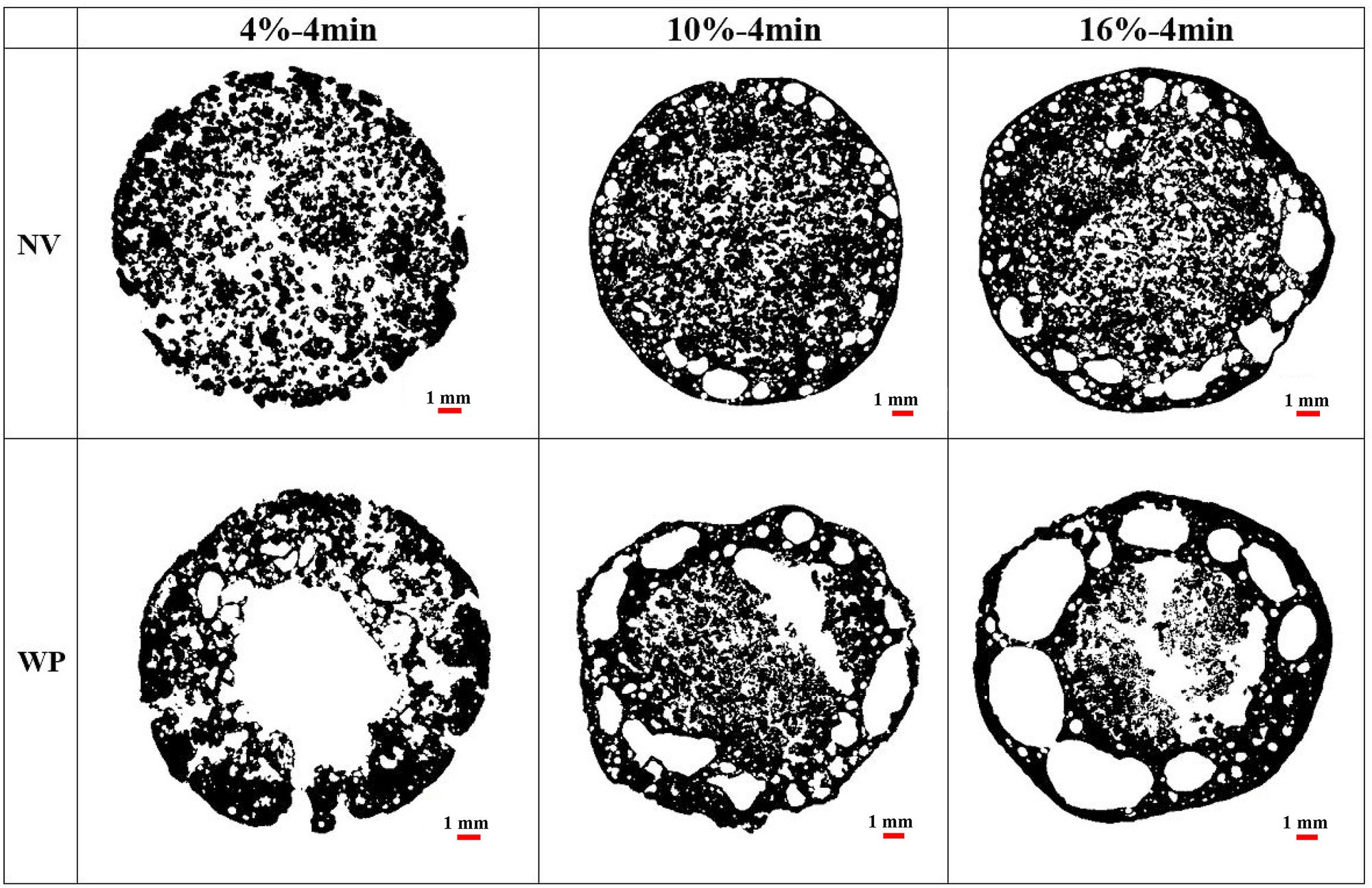

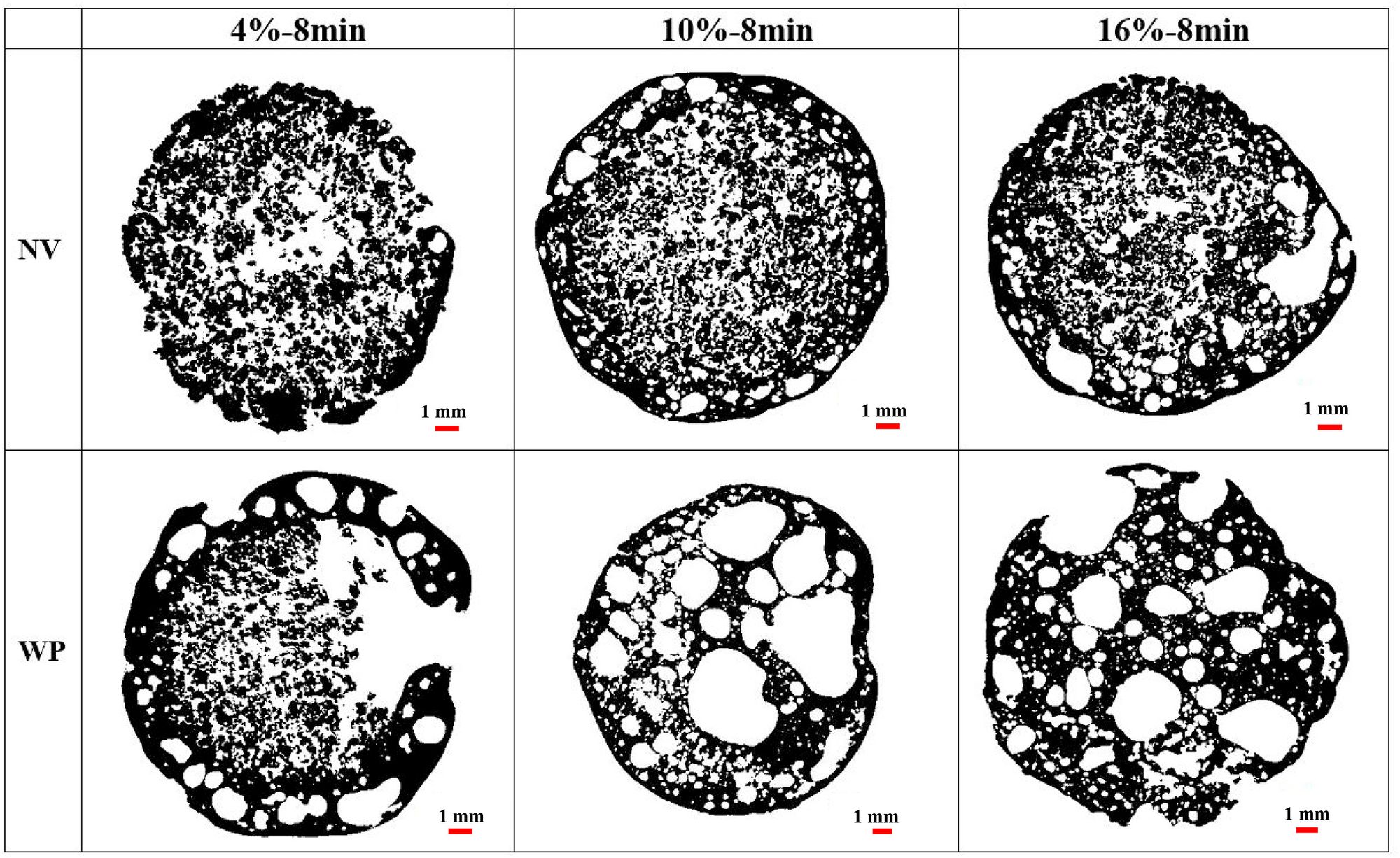

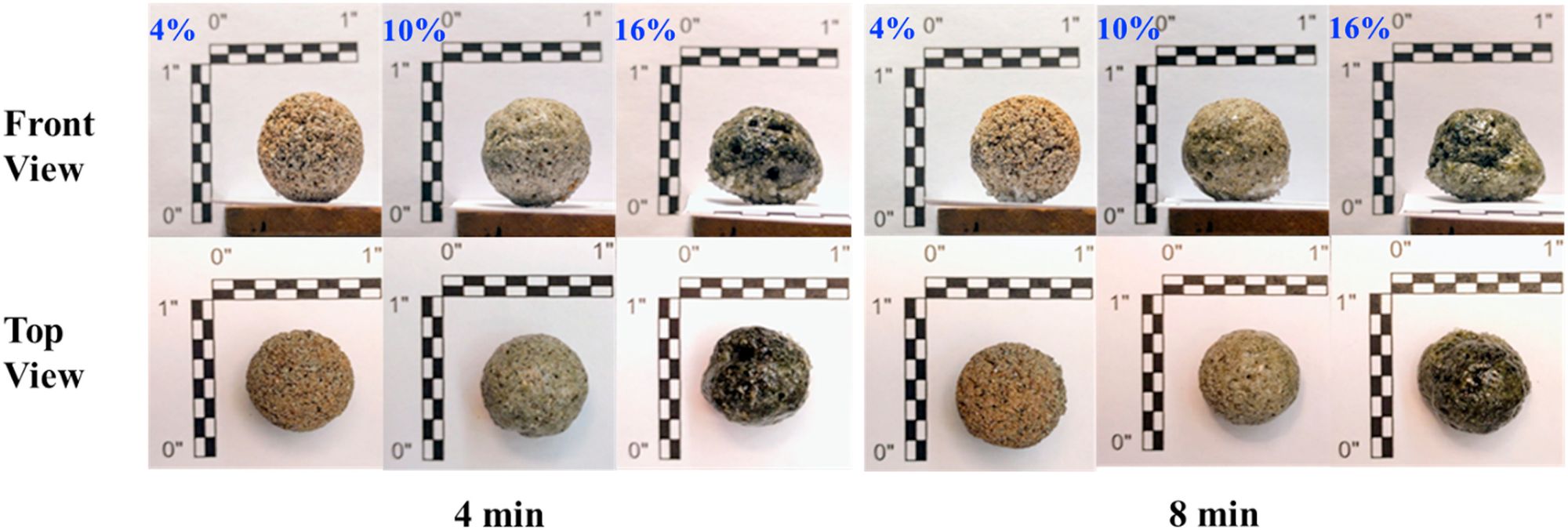

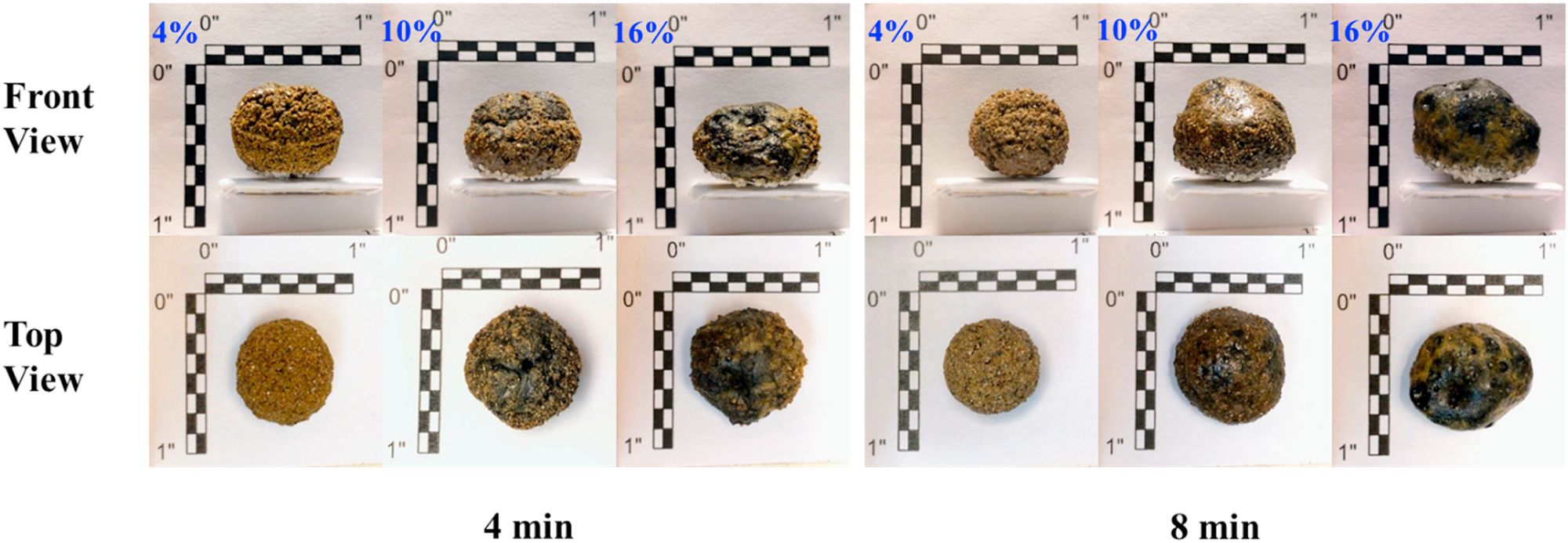

The result is a new raw material called “spherical porous reactive aggregate” or SPoRA, for short. It is made by combining coal ash with chemicals that help sinter and bond the aggregate into tiny spheres which are then baked for a few minutes at 1,160° Celsius. This produces a pellet that can hold almost half its weight in water, far exceeding the water retention abilities of traditional aggregates.

Significantly, the pellet also releases its water at a steady rate, allowing the cementing mix to cure evenly.

“As the concrete begins to cure on the outside, the aggregate pellets are also releasing their moisture to help it cure from the inside out as well,” says Balapour. “This approach can help to maximize the durability of the concrete. And the SPoRA-making process is simple enough to produce aggregates of any size and water capacity, so we believe it could be used for a number of applications in the construction industry.”

The study, now published in the journal Cement and Concrete Composites, highlights the advantages of using these spheres, stating that, “SPoRA possesses three main features that make it a better lightweight aggregate (LWA) in comparison to commercial LWAs: a spherical shape to increase the workability of concrete, better sorption properties to absorb and desorb water for internal curing, and a glassy surface with crystalline internal structure to provide surface reactivity with the cementitious matrix while possessing desirable internal crystalline strength.”

These are a significant assets in a world that is demanding more and more from construction materials, with modern architecture coupled with the need to build bigger and higher structures making concrete work harder than ever.

Moreover, by using a waste product that has a major ecological impact on regions that burn coal for electricity, the spheres are helping to make concrete production more environmentally friendly.

As Farnam highlights, “Taking something that is a waste product - with mountains of it in landfills - and turning it into a useful product is an excellent example of how science can help to find sustainable solutions to society's challenges. Not only does this help protect our natural environment but it will also help to improve our built environment.”

Photo credit: ScienceDirect, Cer, Earthjustice, Civildigital, & Keflatwork