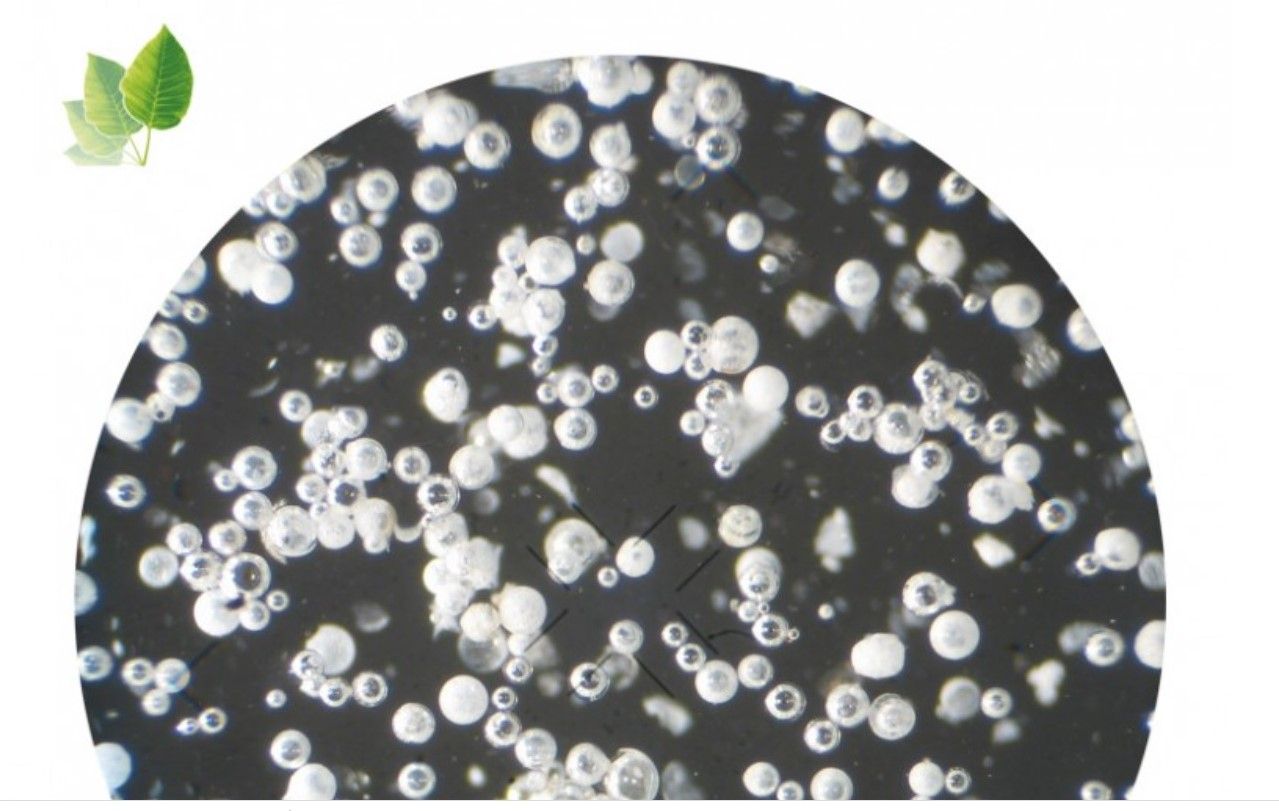

Microspheres look like a powder to the naked eye, but are actually tiny spheres of alumina-silicate recovered from the waste ash from coal-fired power stations.

They are a valuable raw material where extreme heat and mechanical resistance is needed. They are also a practical solution where big volume and high strength is required alongside low weight.

Microspheres are typically white or grey, depending on what was burnt for how long and at what temperature, and the wall thickness of the spheres. Lighter colours are more helpful in reflecting heat away when used as a refractory material.

What are Microspheres?

Microspheres are a generic term for any small spherical particles which measure less than 1mm in diameter (although are typically 500 microns or less). As an industrial raw material, microspheres are usually the ceramic particles found in fly ash from coal-fired power station waste, but can also be extracted from ancient volcanic rock.

There are three basic types of structure:

· Cenospheres which are hollow.

· Precipitators which are solid.

· Plerospheres are slightly larger, hollow balls which are filled with either precipitators or cenospheres.

While the fossil fuel origins of microspheres make them unsustainable, they are often seen as a more ecologically friendly chemical feedstock than other materials, as they find a use for power station waste.

Fly ash is a major waste problem with some of it being blown away to pollute the air and millions of tonnes requiring disposal (typically burial) each year. Although, microspheres constitute only 1%-3% of fly ash, the recycling of any waste is environmentally helpful.

According to National Geographic magazine, “Fly ash and the other residuals of burned coal add up to one of the largest waste streams in the United States: More than 136 million tons per year. In Europe, coal waste totals 100 million tons per year by some estimates.”

While this figure is slowly falling as developed economies move away from fossil fuels, the situation in other countries is almost certainly worse. For example, data is lacking on the actual amount of fly ash created in China, but a 2017 study estimated that the country produces 600 million tons of coal-ash per year.

“The cost of microspheres varies considerably,” notes the industry journal Composites World, “depending on a variety of factors, including material, density, strength and volume.”

One source of good quality microspheres is AG CHEMI GROUP. With more than 27 years of experience in supplying raw materials to industry, AG CHEMI GROUP is a trusted name among manufacturers.

The microspheres they supply are filled with nitrogen and carbon dioxide, and have the following advantages:

· High melting point 1300 – 1710 °C

· High compressive strength in composite solution and materials

· Non-flammable

· Improves thermal insulation

· Improves impact resistance

· Increases stiffness and nail/screw grip

· Reduce weight in composite solution and materials

· Rheological stable

· pH neutral

· Chemically inert and non-absorbent

· Very low reactivity

· Extremely resistant to acids and alkalis

If you would like to learn more about the microspheres offered by AG CHEMI GROUP, then please contact Eugene on +420 775 192 267 or Evzen.Hreben@agchemigroup.eu.

Alternatively visit AG CHEMI GROUP.

Photo credit: Kelly L from Pexels, Viviane Okubo on Unsplash, Universal Eye on Unsplash, Alex Fox from Pixabay, & AG CHEMI GROUP,