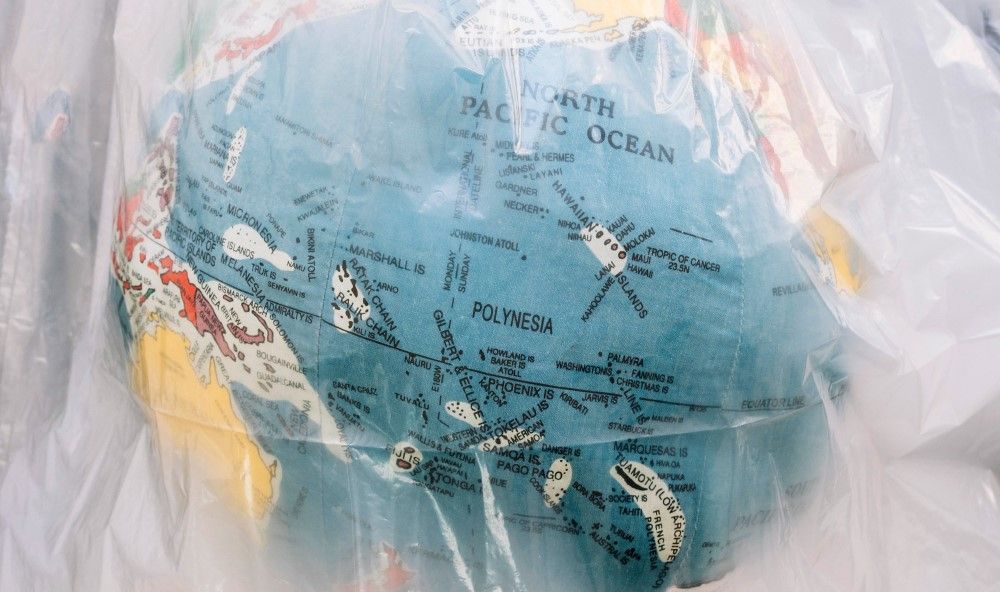

The science is overwhelming - the most pressing issue of our time is climate change. The cause of climate change is humankind’s increased production of greenhouse gases (76% of which is carbon dioxide).

Efforts to reduce CO2 emissions rely heavily on burning less fossil fuel through better insulated homes or generating more renewable energy. Alternatively, planting more trees (or cutting less down) will help to absorb more carbon dioxide.

Carbon capture (storing emissions from industrial processes deep underground in geological formations) has also been looked at, but is a very limited technology, as it merely delays the problem for future generations. What is really needed is a process which uses carbon dioxide - turning it into something useful and giving it value.

With fossil fuels used to create more than 390 million tonnes of plastic each year (and growing), turning CO2 into a useful polymer could solve two problems at once. It would find a use for carbon dioxide emissions as well as avoid the need to produce more.

“By definition fossil fuels are produced from the remains of plants, which captured carbon dioxide from the atmosphere,” explains sustainability expert Robert Lilienfeld, the executive director at the Sustainable Packaging Research Information and Networking Group (SPRING) “Pressure and biodegradation turned it into crude oil. So, plastics produced directly from carbon dioxide could theoretically make sense.” However, he also concludes by saying that, “Frankly, I don’t expect that science and economics will support the concept of CO2 polymerization.”

But then again, the experts have been wrong before.

Given the value (to the both the planet and the chemical industry) of finding a path from CO2 emission to polymer, research in this field has been intense and rewarding.

The Dutch sustainable chemical producer Avantium, for example, has created an “electrochemistry to convert CO2 to high-value products and chemical building blocks including glycolic acid. By combining glycolic acid with lactic acid, [the process] can produce polylactic-co-glycolic acid (PLGA), a carbon-negative polymer with valuable characteristics.”

These include:

· Robust mechanical properties

· An effective barrier for moisture and oxygen

· Recyclable

· Marine degradable

· Compostable

Avantium has now teamed up with SCGC to “scale-up to a pilot plant with an indicative capacity of 10 tonnes per annum.”

CO2 is also the focus feedstock for the BioCO2-Trapping project funded by the Italian-based Cariverona Foundation.

This initiative, head by Stefano Campanaro, professor of the Biology department of the University of Padua, is centred on the bacterium, Cupriavidus necator.

“It is an extremely interesting microorganism for our study,” says Campanaro. “In fact, it is known that, when it finds itself in stressful situations, perhaps in nutrient deficiency, its enzymes begin to transform CO2 into polyhydroxyalkanoates (PHA), basic polymers fundamental for the production of bioplastics.”

The science therefore supports the possibility, and if the process can be upscaled well, then the economics could quickly follow suit.

Notably, if a recent report on the use of carbon dioxide as a polymer feedstock is to be believed then, the change could happen sooner than expected.

The report, published by Fact MR, a market research organization, has estimated that the market for CO2-sourced polymers will expand from $2.28 billion in 2022 to $6.94 billion in 2033 – a compound annual growth rate of 4.5%.

Specifically, the report explains this growth on the following factors:

Short Term Forecast (2023-2026): increased consumer demand for eco-friendly products will provide the market with strong short-term development momentum.

Medium-Term Forecast (2026-2029): Further market expansion will be driven by rising collaboration efforts among the major polymer manufacturers and academic and research institutions. This will provide an improved understanding of CO2-based polymer technologies, promote innovation, and accelerate adoption across various industries.

Long-Term Term (2029-2033): As the impact of climate change becomes more obvious and as the deadline for company pledges draws near, long-term demand for sustainable materials like CO2-based polymers will increase. Similarly, as climate change impacts people’s lives more and more, governmental laws and policies will be more stringent, with larger subsidies for sustainability and heftier penalties on fossil fuels and plastic waste.

Interestingly, the report focuses on polycarbonates (PC) as a sector of the plastic industry where CO2 feedstocks may garner most interest.

The report also highlights Germany as one of the most developed producers, stating that, “[Germany] is strongly committed to both the Paris Climate Change Agreement and the 2030 Agenda to attain sustainability. Germany's strong focus on sustainability and environmental responsibility has driven the adoption of CO2-based polymers as an eco-friendly alternative to traditional plastics.”

India is also noted as a likely candidate for leading the sustainable polymer sector, as it has limited fossil-fuel feedstocks, an under-funded plastics waste management system, and a rapidly growing chemical industry.

At present, due to technological challenges there are limited commercial applications for polymer products manufactured from CO2. But as advances are made and current higher production costs are reduced through up-scaling it is likely that the market will respond positively.

Most notably, as oil resources become scarcer the long-term price will rise forcing polymer producers to look for cheaper feedstocks.

As Campanaronotes, “The current production of bioplastics is considered rather expensive, especially because it starts from noble sugars, such as glucose, which could be destined for other uses. CO2, on the other hand, is available in large quantities and practically free.”

Photo credit: Freepik, Pixource on Pixabay, Freepik, ear_kkk, & Freepik