Chemical industry research is often inspired by surprising circumstances.

So it is, that a team from Rice University in California have turned to vitamin B12 and a bacteria found on the ocean floor to make a breakthrough in olefin production.

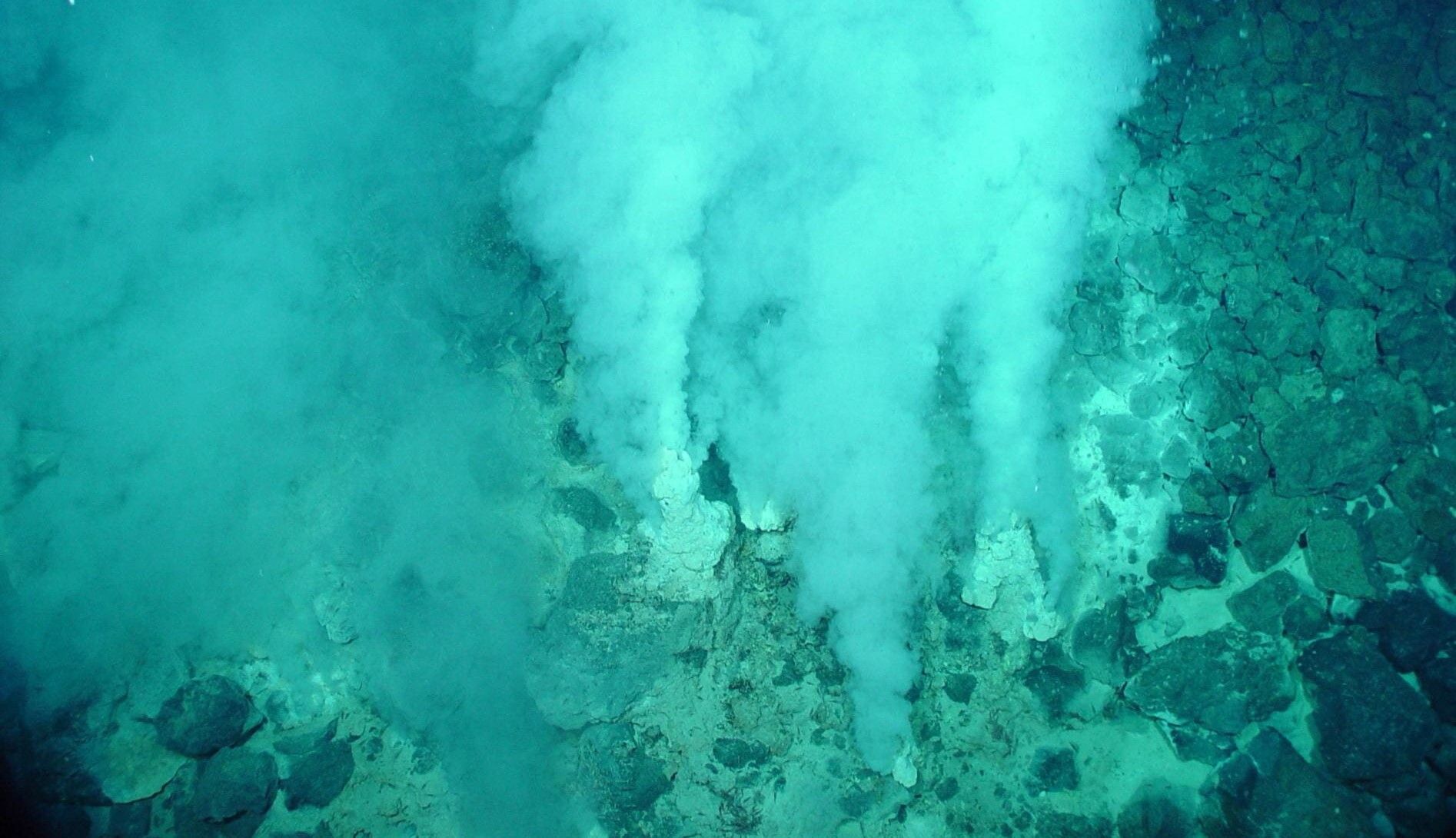

Building on earlier works on metal catalysts and a study on the light-sensitive bacteria called thermus thermophilus which live around underwater thermal vents, it is a discovery that could lead to the production of pharmaceuticals and agrochemicals without the need for harsh chemicals or extreme conditions.

“Arguably, these olefins, or alkenes, are the most useful functional groups in a molecule,” said Julian West, an assistant professor of chemistry at Rice who led the study. “A functional group is like a foothold in climbing: It lets you get to where you want to go, what you want to make.”

While the research has not found any new products, it has started a path towards a less hostile way to make some of the chemical industry’s most important products.

“We’ve had methods to make olefins for a long time, but a lot of these classic methods—late 19th or early 20th century—use incredibly strong bases, things that would burn you and would definitely burn your molecule if it had anything sensitive on it,” explains West. “The other issue is that such harsh conditions might be able to make this olefin, but you might make it in the wrong place.”

According to West, the bacteria thermus thermophilus is able to live on underwater thermal vents thanks to the wide variety of unusual enzymes that it makes.

“One of them is called CarH,” said West, an enzyme which he describes as, “a photoreceptor like a bacterial retina that developed on a parallel evolutionary path to what led to our eyes.”

What is so interesting for industrial chemists about CarH is that it has an alternative, greener route to making useful chemicals.

“Instead of needing heat and strong bases,” said West, “it only needs light energy.”

As the university press release explains, “CarH incorporates vitamin B12 and cobalt that reacts with light and prompts the formation of an alkene, which in turn alerts the organism to light's presence. The Rice team used B12 and the cobalt it contains with sodium bicarbonate (aka baking soda) as a mild base to make the olefins under blue light at room temperature.”

What makes this discovery even more practical for the chemical industry was, “… the appearance of remote elimination, by which they were able to position hydrogen atoms to facilitate further reactions. That could lead to two-step processes for specific products.”

A further surprise was in finding that the olefin product that is so valuable to the petrochemical industry is irrelevant for the bacteria.

“[It’s] just a by-product. It doesn't really care. But we thought we could take this cue from nature,” said West. “Basically, we found we could make olefins and not just isolate them. [Instead] In the same flask at the same time, we can have a second reaction and turn them into something else. This could be a plug-and-play method where we can start to sub in different molecules.”

The study has now been published in the Royal Society of Chemistry’sjournal Chemical Science, where the team explain how, “Nature has pursued a complementary approach in the novel Vitamin B12-dependent photoreceptor CarH, where photolysis of a cobalt-carbon bond leads to selective olefin formation under mild, physiologically-relevant conditions.” Reporting on a “light-driven B12-based catalytic system that leverages this reactivity to convert alkyl electrophiles to olefins under incredibly mild conditions using only earth abundant elements.”

The plan is now to develop the process further, so that it is both practical and economically viable for industrial production of olefins such as polypropylene or polyethylene. From there it is just a short route to a wide variety of plastic products.

Photo credit: Marcel Aniceto from FreeImages, RiceUniversity, Tirachard Kumtanom from Pexels, & Paweł Jagielski from FreeImages