Scientists have found a way to use living microbes as tiny factories for converting carbon dioxide into industrial chemicals.

Using only light as a stimulus/power source, the team from the University of Colorado Boulder discovered that they could modify microbial cells so that they would consume CO2 and release useful chemical products.

The impact of the study could revolutionise the chemical industry; finding a way to biochemically manufacture ammonia, biodiesel fuels, environmentally friendly gasoline, and biodegradable plastics using CO2 as a feedstock.

“The innovation is a testament to the power of biochemical processes,” says Prashant Nagpal, an assistant professor at the University of Colorado Boulder's Department of Chemical and Biological Engineering and the study’s lead author. “We're looking at a technique that could improve CO2 capture to combat climate change and one day even potentially replace carbon-intensive manufacturing for plastics and fuels.”

The study began in 2013 when the researchers were exploring the capabilities of nanoscopic quantum dots (QDs). These are tiny semiconductor crystals or particles which measure only a few nanometres in size. Due to the physics of the very small (quantum mechanics), QDs have exceptional optical and electronic properties.

The breakthrough came when the team began injecting QDs into living cells. Specially designed QDs were then created that would attach and self-assemble onto specific enzymes inside these cells. This gave the researchers the ability to issue commands to those enzymes using specific wavelengths of light.

They already knew that some enzymes in the cells of a common microbial species found in soil has the ability to convert airborne nitrogen and carbon dioxide, but it does not naturally do so because of a lack of photosynthesis. By doctoring the enzymes, the researchers are able to switch on this ability.

All that is needed is a small amount of light to activate the microbes’ appetite for CO2 without needing a source of energy food to carry out the energy-intensive biochemical conversions.

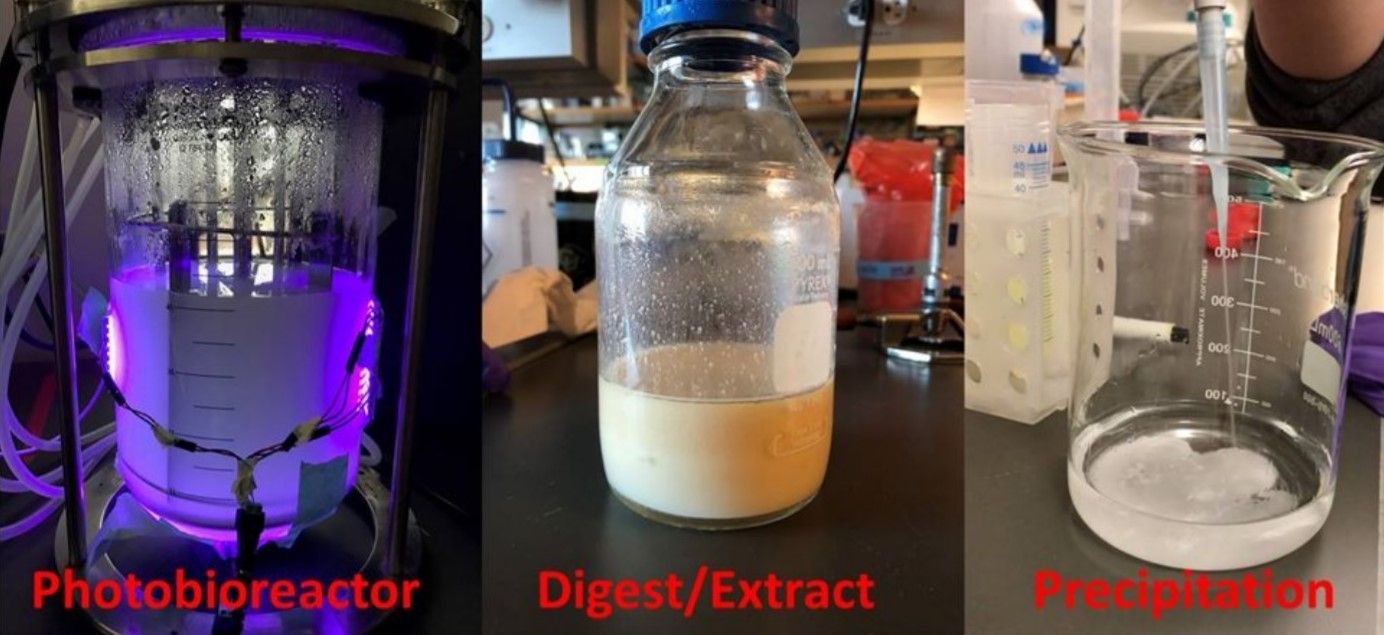

The result is a controlled biochemical process, as the University of Colorado press release explains, “The microbes, which lie dormant in water, release their resulting product to the surface, where it can be skimmed off and harvested for manufacturing. Different combinations of dots and light produce different products: Green wavelengths cause the bacteria to consume nitrogen and produce ammonia, while redder wavelengths make the microbes feast on CO2 to produce plastic instead.”

“Each cell is making millions of these chemicals,” notes Nagpal. “And we showed they could exceed their natural yield by close to 200%.”

The team have now published their results in the Journal of the American Chemical Society, which describes how, “… seven different core–shell quantum dots (QDs), with excitations ranging from ultraviolet to near-infrared energies, couple with targeted enzyme sites in bacteria. When illuminated by light, these QDs drive the renewable production of different biofuels and chemicals using carbon-dioxide (CO2), water, and nitrogen (from air) as substrates.”

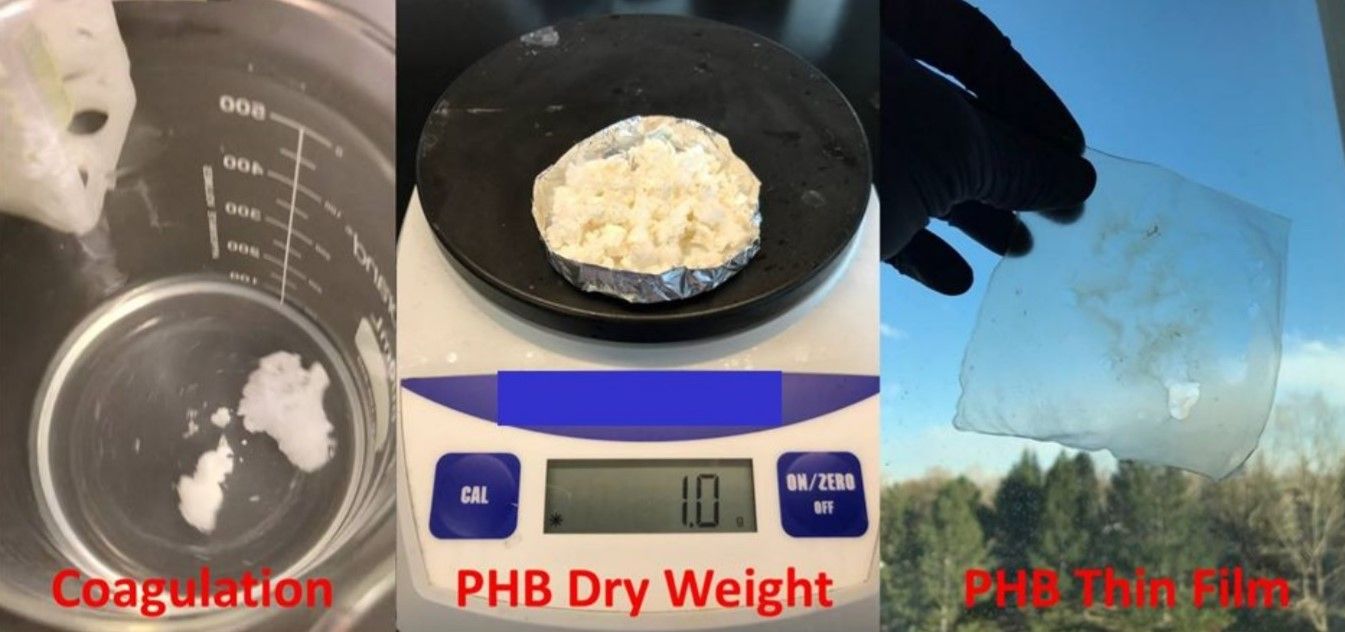

Specifically, that, “… these nanorgs catalyse … [an] air–water–CO2 reduction … to biofuels like isopropanol (IPA), 2,3-butanediol (BDO), C11–C15 methyl ketones (MKs), and hydrogen (H2); and chemicals such as formic acid (FA), ammonia (NH3), ethylene (C2H4), and degradable bioplastics polyhydroxy butyrate (PHB).”

More work is required to both optimize the conversion process and to find out if such a system would be practical for industrial chemical production.

However, these modified microbes have given biochemists a positive first step towards carbon sequestration and new processes for eco-friendly chemical manufacturing. Possibly in the future, individual homes could maintain small ponds stocked with organisms that could convert atmospheric CO2 into a useful chemical product.

“Even if the margins are low and it can't compete with petrochemicals on a pure cost basis, there is still societal benefit to doing this,” Nagpal said. “If we could convert even a small fraction of local ditch ponds, it would have a sizeable impact on the carbon output of towns. It wouldn't be asking much for people to implement. Many already make beer at home, for example, and this is no more complicated.”

The team already believe that the cells are self-regenerating, as the microbial factories they have established have run for hours without showing signs of depletion or exhaustion.

“We were very surprised that it worked as elegantly as it did,” said Nagpal.

While capturing the end chemical product may prove the sticking point that prevents industrial chemical production from soil microbes, the team have at least opened the door on the possibilities available for practical, biochemical processes.

The biochemistry of these microbes is truly amazing. As the study concludes, “… these resting cells function as nanomicrobial [chemical] factories powered by light.”

Photo credit: Journal of the American Chemical Society, & UniversityofColorado