Lithium-ion batteries have enabled the digital world. Without small, rechargeable batteries laptops would not be portable and mobile phones would be heavy, impractical objects.

Yet modern battery design still has its limitations. The lifespan of a lithium-ion battery is quite short, deteriorating quickly after as few as 500 cycles. They hold a relatively small amount of electricity, and they take a long time to charge up.

Many of these problems are caused by the use of silicon in the battery’s anode.

While silicon possesses a high energy density, it substantially expands during charging by as much as 300%. The resulting contraction during discharge causes cracking in the silicon particles which reduces contact and negatively impacts the battery’s performance.

Nanotechnology is now advancing battery design in ways that can increase power output ten-fold, boost longevity five-fold, and can hold a charge three times larger than regular batteries.

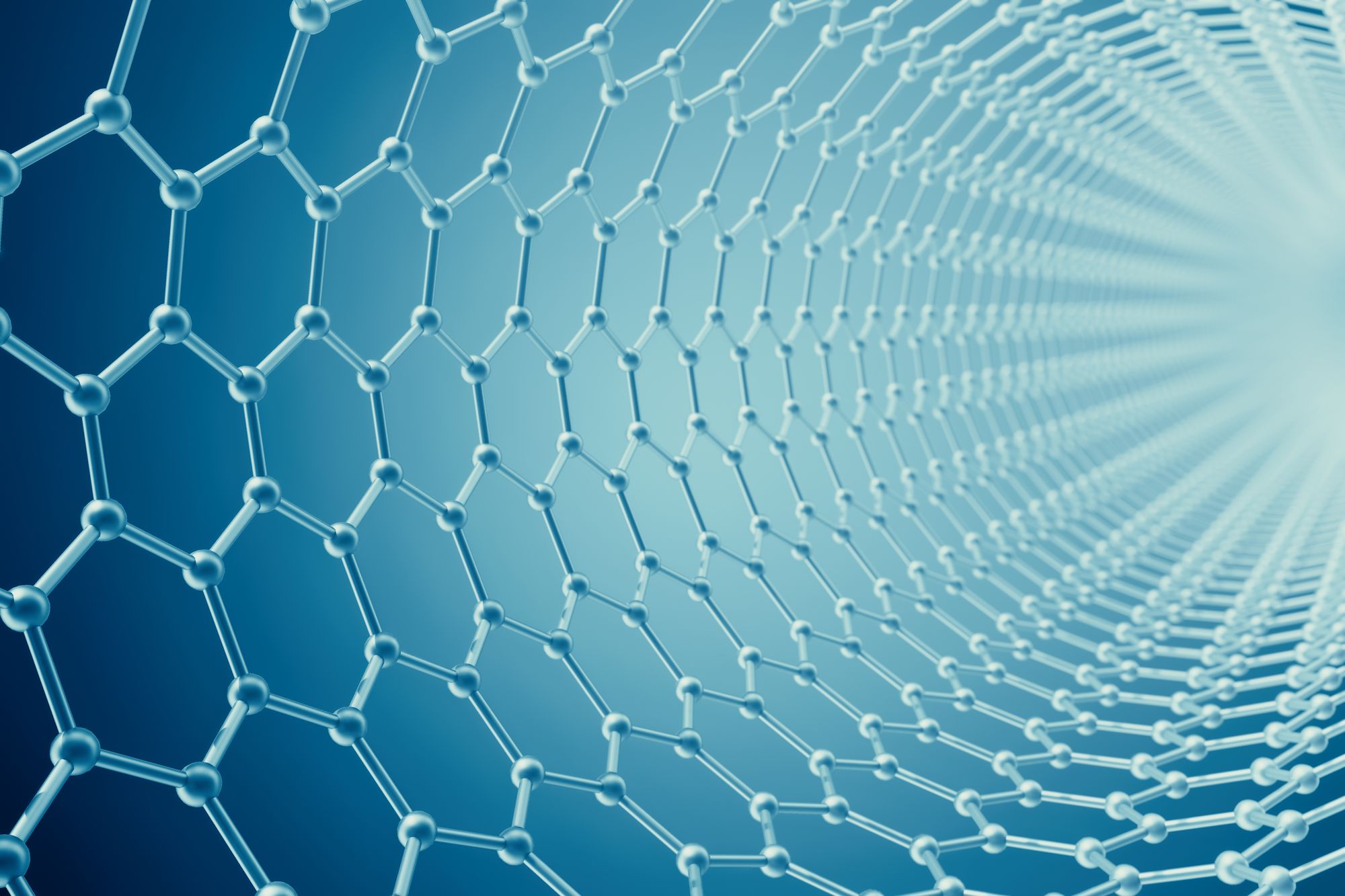

The breakthrough is possible thanks to carbon nanotubes – nanomaterials which range in size from as small as a few atoms but are not larger than a single virus.

Their usefulness is based on their unmatched conductivity. Carbon nanotubes (CNTs) are also strong and flexible, and when correctly placed in a lithium-ion battery can form long-lasting electrical connections between the silicon particles. At the same time, due to their small size, manufacturers can place as many as 100 billion nanotubes on a square centimetre of electrode. This creates a network of nanotubes which is so dense, strong, and conductive, that the battery can still perform to a high standard even when the silicon particles have cracked and are damaged through age and cycling.

In addition to obvious applications in phones, laptops, and other portable gadgets, the application of nanomaterials in batteries is helping the automobile industry. It is a sector where battery technology is severely failing to meet customer demand, reducing electric vehicle sales through long charge times, short ranges, and lifecycle limits.

Yet with carbon nanotubes added, electric vehicle battery designers believe that power storage could be doubled, allowing for distances of more than 1,000 km to be achieved from a single charge, with an 80% charge possible in as quickly as five minutes.

In addition to helping remove fossil fuel dependency, nanomaterials are also improving safety.

Current battery technology has a very low fire risk. But however unlikely, the situation still forces airlines to consider mobile phone and laptop storage in their safety procedures.

With the inclusion of carbon nanotubes the risk of overheating and combustion can be considerably reduced as even a small amount of nanomaterial can lower internal battery cell resistance.

This is the result of a more stable conductive network created by the nanomaterial inside the cathode which means that even after multiple battery charge–discharge cycles and varied battery storage periods, the risk of a battery fire is minimised.

However, the ability of carbon nanotubes to advance battery design is not their only trait.

Instead, carbon nanotubes are improving a vast range of products and materials, such that they are currently used by manufacturers to add properties to everyday products such as plastics, construction materials, coatings, resins and more.

Some of these properties include:

· Increased strength

· Increased rigidity of flexibility

· UV protection

· Thermal conductivity

· Chemical resistance

· Antibacterial properties

· Scratch resistance

· Impact strength

· Electromagnetic properties

· Electrical conductivity

Designing these nanotechnology processes is not always straight-forward, but the rewards offered make it good business sense.

This is because, as well as providing unique selling points, applying nanotechnology can actually reduce raw material costs. With nanomaterials able to reproduce the effect of conventional bulk ingredients, it is possible that savings can be made, by replacing traditional feedstock with a nanoscale alternative.

In many areas, regular raw materials have reached their limits. Customers are demanding ever higher standards, and more and more features on even the most basic of products. It is the natural order of progress, and those who fail to follow risk being left behind.

The battery technology of the past no longer fits market needs.

Instead, a new generation of power reserves are needed. Batteries which charge up faster, have a longer lifespan, hold a bigger charge, and degrade slower even after thousands of cycles.

The ability of carbon nanotubes to develop robust, conductive, reinforcing networks inside active materials, even at ultra-low working dosages, is evidence of how the future of battery design, and in manufacturing in general, lies in nanotechnology.

Photo credit: Mike, Lukas, Markus, Pok Rie from Pexels, & Freepik