For centuries paint has been much more than a decorative coating. It has been the first line of defence against corrosion, abrasion, stress, strain, chemical erosion, rot, and even radiation.

People have protected wood, plastic, metal, and even glass by the application of a thin, yet physical layer of paint or varnish.

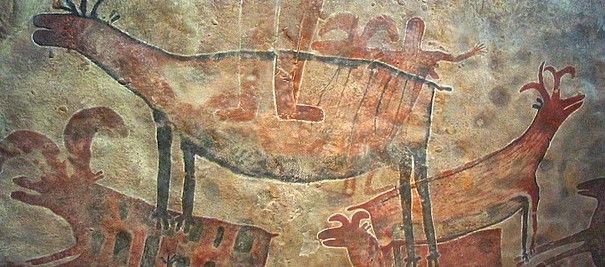

Throughout its long history, paint has seen periods of rapid development since prehistoric man used chalk, blood, and natural dyes to cover cave walls.

In the 1950s, coating manufacturers created thermoplastic acrylic lacquers and the use of metallic pigments. In the 1970s they devised electrodeposition primers to prevent cars from rusting, while more recently the invention of water-reducible acrylics and polyesters, acrylic latexes, and finally polyurethane dispersions in the 1990s have advanced the properties of paint.

But today, nanotechnology is taking the coatings industry on its next scientific advance.

Nanomaterials, such as nanoparticles, nanotubes, and nano rods, measure less than 100 nanometres in diameter. At this scale, substances operate differently to how they perform at a macroscale.

A substance can therefore be made stronger, more flexible, magnetic (or not), electrically conductive (or not), thermally conductive (or not), or more rigid, with the inclusion of these tiny raw materials.

What this means for the coatings industry is that paint and varnishes can be given new properties.

For example, the addition of titanium dioxide nanoparticles can make paint that does not need cleaning.

As the nanomaterial industry journal Nanopartikel, explains, “Nano titanium dioxide is used in paint to exploit two of its excellent properties: (i) photocatalytic activity and (ii) UV-protection.” Specifically, “The combination of the photocatalytic effect, along with hydrophilic properties results in a paint’s self-cleaning effect. The surface will no longer need regular cleaning as the water and dirt will no longer stick on it.”

Meanwhile, adding nanoparticles of silicon dioxide to a paint’s mix can improve a coating’s hardness and resistance to abrasion, scratching, and the weather. Unfortunately, nano silicon dioxide also limits the elasticity of paint, thus shortening a coating’s lifespan as it is less able to expand and contract naturally through temperature and humidity changes.

One company that is taking advantage of the nanotechnology revolution in the coatings industry, is the Prague-based AG CHEMI GROUP (who host this web page). Building on their almost 30 years of expertise in supplying industrial raw materials, they have developed a portfolio of nanomaterials for use in paints as well as a variety of patented processes for improving a coating’s properties.

As Lev Lyapeikov, the product development manager at AG CHEMI GROUP explains, “Nanomaterials add new properties to resins and paints without adversely affecting the physico-chemical base of the material, which distinguishes our solution from conventional market offerings. For example, the traditional use of black carbon black reduces the mechanical strength of polymers and limits the entire colour gamut to a single colour outcome. But not so with our solution.”

One of the key advantages of nanomaterials, is that their size provides a large surface area to weight ratio. This means that the inclusion of just a small amount of nanomaterial can have a marked effect on a coating’s abilities.

“The technology developed by our company allows us to work with a wide range of nanomaterials of various concentrations,” says Lyapeikov. “For example, we can create a solution with a concentration of 0.015% nanomaterials that has excellent functional properties. Or we can produce a composition containing up to 10% nanomaterials with a specific surface area of up to 1000 m2 per gram.”

Like any new scientific advance, nanotechnology has its sceptics.

As Dr Peter Wick, from the Swiss Federal Laboratories for Materials Science and Technology (Empa) and author of ‘Is Nanotechnology Revolutionizing the Paint and Lacquer Industry? A Critical Opinion’, writes, “At the time there is no guarantee that the nanomaterials in paints and façades will fulfill their task in the long run, since there are no long-term studies available.” Concluding that, “Thus at this time it is still unknown if it makes sense to incorporate nanomaterials into paints. Intensive research and development are still needed in order to find the answers.”

Research to find negative side-effects from using nanomaterials as a raw material in paint and varnish has yet to show significant risks to health, although studies are still ongoing.

Significantly, one clear advantage gained from nanomaterial inclusion in paint can be addition of antibacterial and antiviral properties.

As long ago as 2008, a study published in the journal Nature Materials found that, “… surfaces coated with silver-nanoparticle paint showed excellent antimicrobial properties by killing both Gram-positive human pathogens (Staphylococcus aureus) and Gram-negative bacteria (Escherichia coli).”

While a 2010 study in the Journal of Nanobiotechnology found that, “Silver nanoparticles have proven to exert antiviral activity against HIV-1 at non-cytotoxic concentrations…”

Fast forward to 2020, and researchers are now close to finding nanomaterials that can be added to coatings to kill coronavirus. The industry journal Coatings World reporting that, “Literature survey shows that the nanoparticles (NPs) of various metals and metal oxides like Zinc Oxide nanoparticles (ZnONPs), Cuprous Oxide nanoparticles (CuONPs), Silver nanoparticles (AgNPs), Nanosized Copper Iodide particles (CuINPs), Gold nanoparticles on Silica nanoparticles (Au-SiO2NPs) and also some Quaternary ammonium cations commonly called QUATs are very promising to inactivate the virus and are well proven.”

Nanotechnology in coatings clearly has much to offer.

The properties that nanomaterials can soon provide to paint may have limits close to what is today seen as science fiction.

Can copper nanoparticles make a coating electrically conductive, turning a wall into a computer screen? Can nanomaterials make hospital surfaces antibacterial? Can nanomaterials make paint protective against extreme heat? Or cold? Or radiation?

While some of these concepts may remain as pure fantasy, the developments being made by nanomaterial specialists in improving the range of coatings being made should not be ignored.

Paints and varnishes have constantly needed upgrading, and now is the time for nanotechnology to play its role in their history.

Photo credit: Markus Spiske on Unsplash, Unsplash, Joey Huang on Unsplash, National Cancer Institute, Rodrigo de la torre from Pixabay, & Myriam Zilles from Pixabay