In a very health-conscious year, everyone is focused on preventing infection and on staying healthy.

Taking a leading role in this is the nanotechnology sector who are working with raw material manufacturers and suppliers to make polymers and synthetic fibres with anti-bacterial and possibly even anti-viral properties.

At the centre of the development of these products is NANO CHEMI GROUP, a Prague-based supplier of nanotechnology processes and nano additives.

Here is an outline of the technology used, what the company makes, and how nanomaterials are improving the everyday products we all use to avoid getting sick.

The Nanomaterial Processes – What we use.

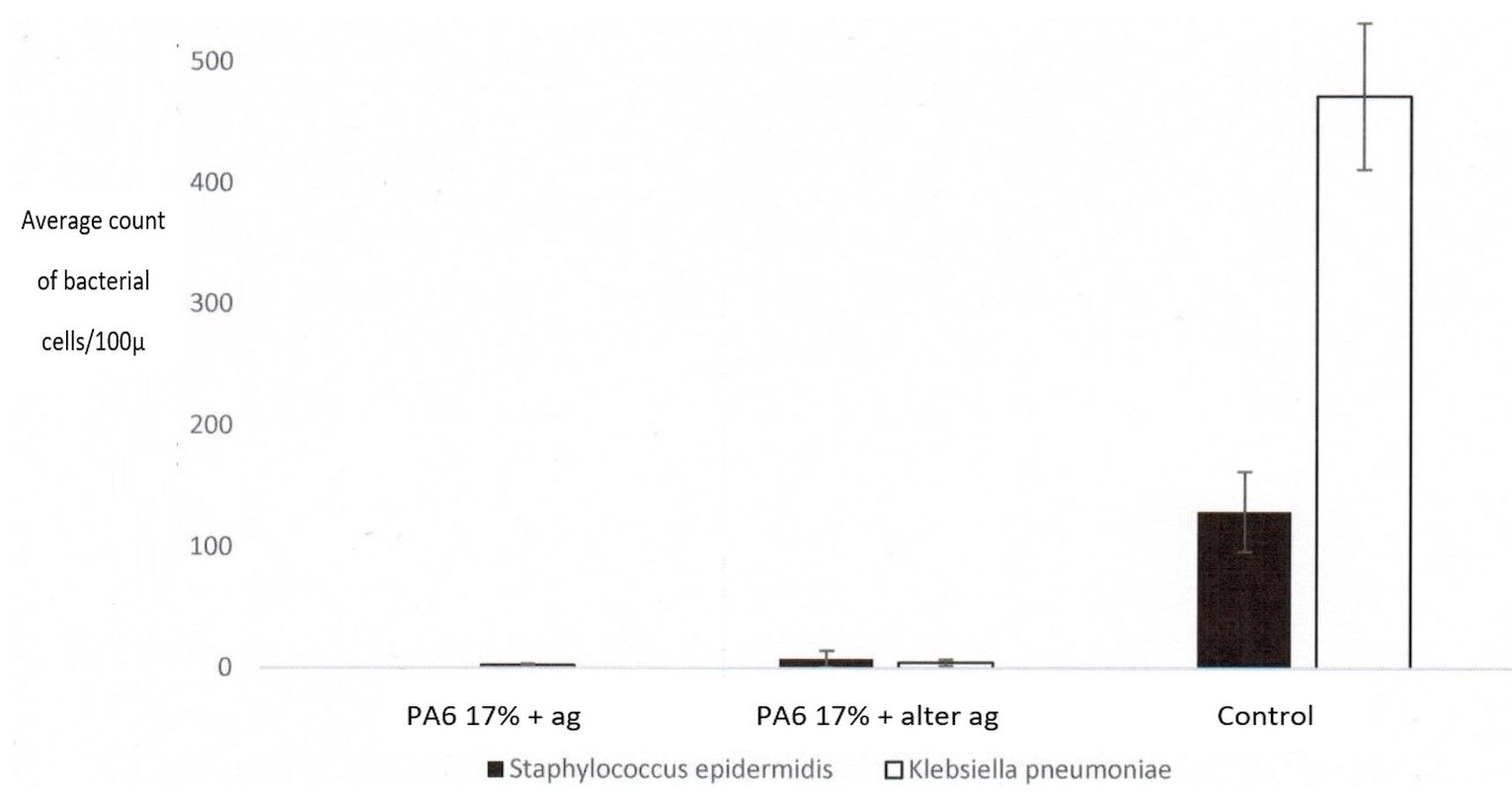

NANO CHEMI GROUP is in the final stages of developing aqueous and alcoholic solutions with long-lasting anti-sceptic and anti-bacterial properties. These fluids are made with nanoparticles of silver, copper, and cerium - bioactive metals which are well known for their pathogen killing properties.

The company is also developing a process for synthesising biocidal nanofillers. These are made from silver and copper oxide nanoparticles which are processed via electrospinning.

The nanoparticles can then be added directly into polymer mixes such as polypropylene, polyamides, and polycarbonate. By adjusting the concentration level, these nano additives can provide optimal anti-bacterial properties to the finished product.

The Nanomaterial Science – Why Nanomaterials?

The ions of some metals possess bactericidal properties, which, due to chemical reactions of oxidation, destroy the structure of pathogenic microorganisms. The most active are ions can be found in silver, copper, zinc, and cerium – metals used even by ancient civilizations for destroying germs and staying healthy.

However, because nanoparticles have a very high specific surface area, they become much more potent and effective at killing bacteria and possibly even viruses.

These metals are also very stable and so can be a long-term source of active ions. Their high efficiency also means that a very small amount can be added to a polymer mix to provide an anti-pathogen effect without impacting the mechanical or rheological properties of the polymer product.

The Nanomaterial Product – What we make.

This nanotechnology can be applied to numerous types of polymer. For example, one of our processes uses silver nanoparticles in polyamide nanofibers, which are then used to make reusable bactericidal masks.

We are actively testing this solution with our business partners at PARDAM NANO4FIBERS s.r.o.- a unique manufacturer of nanofibers for protective masks and respirators in the Czech Republic.

Different products are also being developed with other Czech companies that manufacture plastics and synthetic fibres. Additional research assistance is being provided by the Institute of Microbiology and Virology at the National Academy of Sciences in Ukraine.

The Nanomaterial Market – Who we make for.

1. Textile manufacturers

Anti-pathogen nanotechnologies are suitable for manufacturers of non-woven synthetic fibres for use in medical masks, respirators, and medical clothing.

Most face masks in use today only provide a simple barrier for pathogens. But with each breath, the wearer is collecting more and more bacteria on the mask’s surface. Here they can remain, sometimes for days, constantly multiplying, waiting for the chance to infect someone.

By using NANO CHEMI GROUP’s nanomaterial additives in the fibres that make up the face mask, the surface of the material can be made to kill bacteria on contact, thus lowering the risk of infection.

2. Polymer manufacturers

Nanoparticle additives for polymer mixes can destroy pathogens on plastic partitions, counters, and protective surfaces. These high contact areas in hospitals, shopping centres, schools, and other public buildings are a well-known breeding ground for bacteria and a major cause in spreading disease.

The use of biocidal nanofillers in these areas can not only restrict how sickness is passed from person to person, but can also limit bacterial infections, such as the so-called ‘superbugs’: carbapenem-resistant enterobacteriaceae (CRE) and methicillin-resistant staphylococcus aureus (MRSA).

These properties make nanomaterial additives ideal for use in film products for medical appliances and can also be used in packaging for the food industry.

Our nanoparticle suspensions are in high demand due to their low-cost, yet safe and efficient performance. Because they are so effective, very little product is needed meaning that the polymers maintain their original properties.

The Advantages of Nanomaterials.

The current pandemic shows the importance of understanding how pathogens can spread. Given the minute size of bacteria, it makes sense to research how materials interact at the nanoscale.

NANO CHEMI GROUP’s cooperation with raw material manufacturers and nanomaterial researchers has found a way to control the spread of germs in both polymers and artificial fabrics.

Meanwhile, our studies are ongoing to develop new ways that nanomaterials can improve everyday products.

In doing so, we are unleashing the power of nanotechnology, not just in the laboratory, but for the improvement of industrial raw materials.

Nanomaterials maybe the size of a marble when compared with the earth, but that doesn’t diminish the significance of nanotechnology.

Photo credit: NANO CHEMI GROUP, Sasin Tipchai from Pixabay, leo2014, & sofisorgin