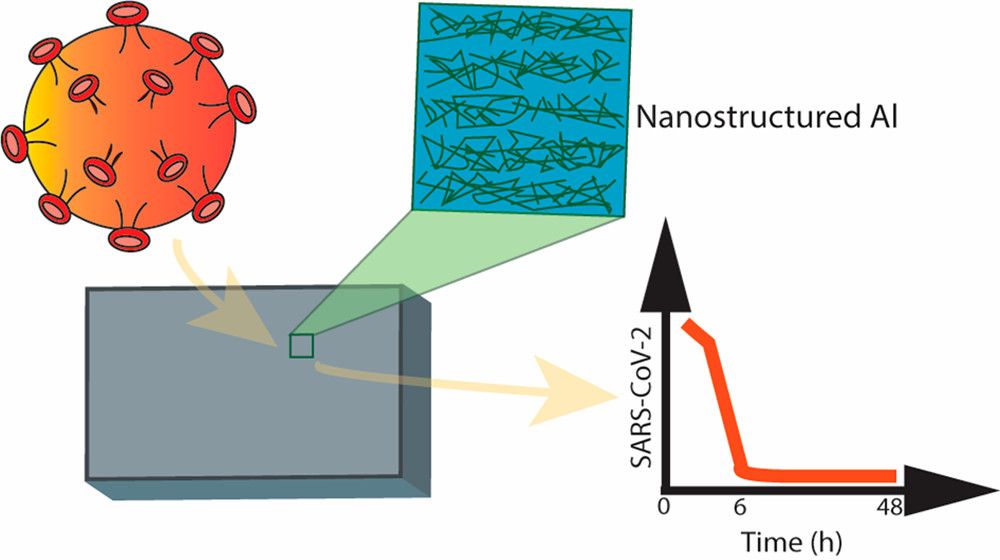

While the world seeks a vaccine for coronavirus, nanotechnology researchers have made a major discovery by nanostructuring surfaces in a way that can deactivate the virus within six hours.

Despite the global effort to wash hands, wear masks, and keep surfaces clean, little research has been conducted on the benefits nanotechnology could provide in the fight against infection. As the nanotechnology journal Nanowerk notes, “Quite surprisingly, so far the effect of nanostructured surfaces on viruses has never been investigated.”

However, a team from Queensland University of Technology in Brisbane have now made a breakthrough that could help limit the spread of coronavirus. The researchers have published their findings in the journal ACS Biomaterials, Science and Engineering, where they, “report the ability of the nanostructured aluminum Al 6063 alloy surfaces to inactivate the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2).”

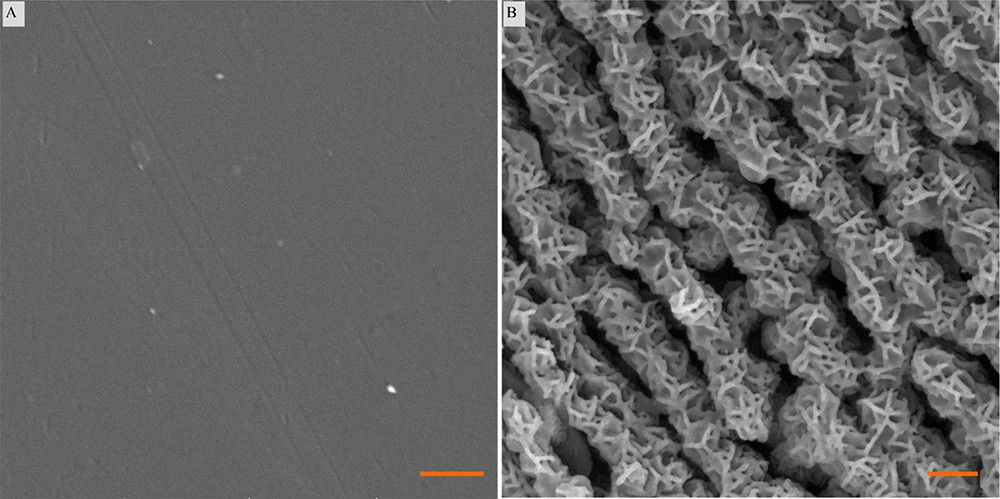

Explaining how, “The nanostructured surfaces were fabricated using wet-etching techniques which generated nanotextured, randomly aligned ridges approximately 23 nm wide on the Al 6063 alloy surfaces. In addition to the excellent mechanical resilience properties previously shown, the etched surfaces have also demonstrated superior corrosion resistance compared to the control surfaces.”

“Our results provide evidence that surfaces that are structured with specific nanoscale surface features are effective in preventing SARS-CoV-2 and the subsequent environmental spread,” said the paper’s first author, Jafar Hasanin an interview with Nanowerk. “Such nanostructured surfaces can be used in hospital environments such as with trolleys, bed-rails, door-knobs etc. These surfaces can be extended to other industrial sectors and public infrastructure such as transportation, where fomites or contaminated surfaces are carriers for viral infections.”

The study built on earlier work where nanostructured aluminium was found to destroy both Gram-positive and Gram-negative bacteria, as well as having some effect on reducing respiratory syncytial virus and rhinovirus was reduced within hours of exposure.

“We have been working in the area of nanostructured antibacterial surfaces for many years,” said Hasan. “As bacterial cells are mechanically ruptured on these surfaces, we hypothesized that if we can create nanostructures smaller than the size of viruses, then maybe we can deactivate or reduce the viability of viruses as well.”

However, this is the first time that they have managed to prove that altering the nanostructure of a surface can directly impact the health of coronavirus.

As Hasan highlights, “We found that upon exposure to the etched surface, the viability of the SARS-CoV-2 virus was reduced significantly within 6 hours compared to exposure to smooth Al control and TCP surfaces. With a 5-log reduction, there was practically no live virus recovered from the etched surfaces at 6 hours of exposure or later.”

The team now plans to better understand why nanostructured surfaces can have an antipathogen effect, as well as explore how well this method works with other materials.

While nanostructuring surfaces to create antiviral materials is making the headlines, entrepreneurs from Prague at the company AG CHEMI GROUP are already hard at work in bringing a pathogen-killing textile embedded with nanomaterials to market.

Called NANO AB PP-25, the textile is made via a process of embedding nanoparticles of copper, zinc, silver, gold, and cerium into fabric. The result is a durable, washable material that can destroy bacteria and viruses on contact.

According to the company’s CEO Igor Sevcenko, the fabric used can be either manmade or natural, and once treated is capable of, “killing 99.99% of all known bacteria and virus.”

While early efforts are being made to put the fabric into production for use in face masks, the wide range of textiles that could be used in the process, alongside its durability, gives the product thousands of potential applications. NANO AB PP-25 could be used in doctor’s gowns and nurse’s uniforms, in bandages to kill bacteria, in hospital waiting room furniture and curtains, in gloves and cleaning cloths, or in restaurant napkins and tablecloths. Anywhere, basically, where there is a risk of infection through contact.

If these approaches completely fulfil their potential, then nanostructured surfaces and embedded nanoparticles may become the most successful fronts in the war against COVID.

Photo credit: ACS Biomaterials, Gerd Altmann from Pixabay, Ryan McGuire from Pixabay, & CDC from Pexels