The first part of this article discussed how trade wars, politics, and natural events can put the steady supply of raw materials at jeopardy. The result is erratic price tracking and unstable supply chains.

To learn more about this topic read: Solutions to Global Disruption of Rare Raw Materials part 1

Such uncertainty is bad for business, hurting both manufacturers and consumers. But are there any answers to these problems?

While urban mining and biocatalysis remain current and future routes to a steadier supply chains, here we examine further solutions to avoiding shortages of rare raw materials.

Raw Materials from Transmaterialization

Another alternative to avoiding supply chain glitches is to replace rare raw materials with common ones; an approach known as transmaterialization.

Advances in this process were summarized in a recent study by Prof. Björn Sandén and Associate Prof. Rickard Arvidsson from Chalmers University of Technology in Sweden. Their analysis of earlier investigations, now published in the Journal of Cleaner Production, explains how, “A number of previous studies have discussed and investigated the potential for substituting scarce materials.” Including, “… the substitution of chromium, manganese, molybdenum, niobium, nickel, vanadium and tungsten in steel by more common materials, such as aluminum, magnesium, nitrogen and silicon. [While] Graedel et al. (2015) investigated the substitution of approximately 60 different metals by substitutes available in the near term.” Additionally, “Several other studies have investigated the availability and potential substitution of scarce materials in solar cells, such as cadmium, telluride, selenium, gallium, indium and ruthenium.”

While the research is ongoing, resulting in an expansion of the number of materials with manufacturable substitutes, most of the processes so far developed are expensive and energy intensive, making the practice of transmaterialization unattractive to most businesses.

Raw Materials from Carbon Nanotubes

In an ideal world, rare raw materials would not only be replaced with common minerals, but with renewable substances. This has led a number of researchers to look again at one of the most renewable materials on earth – carbon.

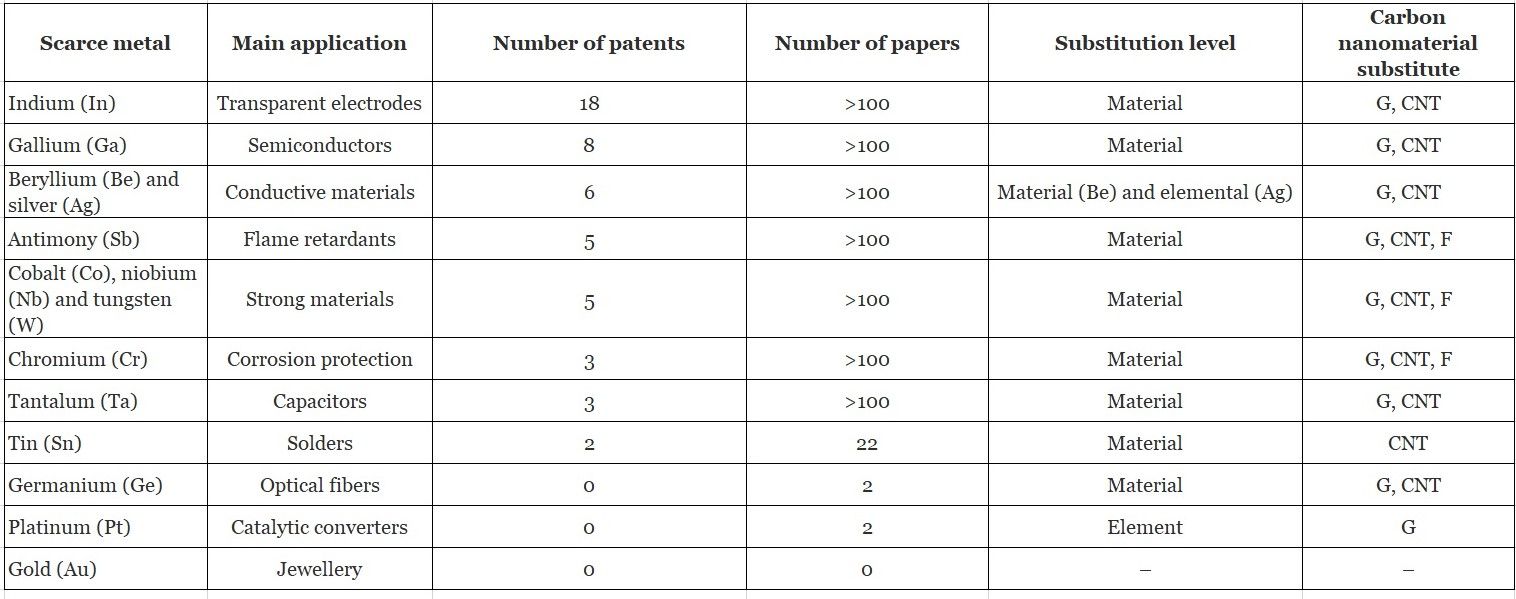

Specifically, researchers are exploring nanoscale carbon materials, such as carbon nanotubes. For example, Sandén and Arvidsson’s study found that research has already, “… identified 14 metals whose use could be significantly reduced if replaced with carbon nanotubes.” Adding that, “There is a growing body of research that indicates significant potential for graphene-based catalysts to replace, or at least minimize, our dependence on platinum, palladium, rhodium and other endangered elements.”

Despite the promise of nanotechnology providing near endless supplies of substitute raw materials, there are still reservations over the technology. As the report states, “There could also be trade-offs with other environmental and resource issues occurring throughout the carbon nanomaterial (CNM) technologies' life cycles. For example, it could be that the increased use of CNMs will also increase the use of some scarce metals that are used in conjunction or during CNM production. One noteworthy example identified was the use of tin, silver, copper and nickel together with graphene and carbon nanotubes (CNTs) in solders.”

However, in general there is a great deal of promise in using nanomaterials as replacements, with the study noting that, “We found early-stage CNM technologies for potential use in the main applications of antimony, beryllium, chromium, cobalt, gallium, germanium, indium, niobium, platinum, silver, tantalum, tin and tungsten.”

Specifically, these advances have real-world applications, with CNM technologies found, “… for transparent electrodes, semiconductors, conductive materials, flame retardants, strong materials, corrosion protection, and capacitors.”

While large-scale changes to historic supply chains and methods of raw material sourcing will take time, it seems that nanotechnology may soon assist with the supply of materials. This is because, as long as commodity markets continue to be unstable and unpredictable, the steady hand of business will seek a more stable price and a more reliable approach to raw material sourcing.

While there is no instant cure to the problems of global shortages of rare raw materials, there does exist great potential for change in these markets.

To find out more on this topic read: Will there be a Global Shortage of Rare Raw Materials?

Photo credit: ACS, Iopscience, Infomine, Financial Times, Twitter, Bulkdistributor, Resource, RSC, ScientificAmerican, Thermofisher, Investorinsights, & Airliquide