Nanotechnology is often hailed as a method of producing next generation raw materials. Nanoparticle drug delivery systems, nanowires to make super computers, or nanotubes that are incredibly light yet stronger than steel.

But it now seems that nanotechnology could even help recycling efforts, as two new methods have been found to turn plastic waste into a practical feedstock.

Turning Waste Plastic into Graphene

The first breakthrough comes from California, where nanotechnology researchers from Rice University have successfully modified an earlier discovery called ‘Flash Graphene’.

The ‘Flash Graphene’ process was able to take carbon and by passing a sudden, extreme heating, electrical direct current through it, could create graphene.

To read more about the original study that found a quicker way to produce graphene read; Graphene Produced in a Flash at a Fraction of the Price

However, the team were not satisfied, and set out to improve the process, while also helping to tackle one of mankind’s most pressing challenges – plastic waste.

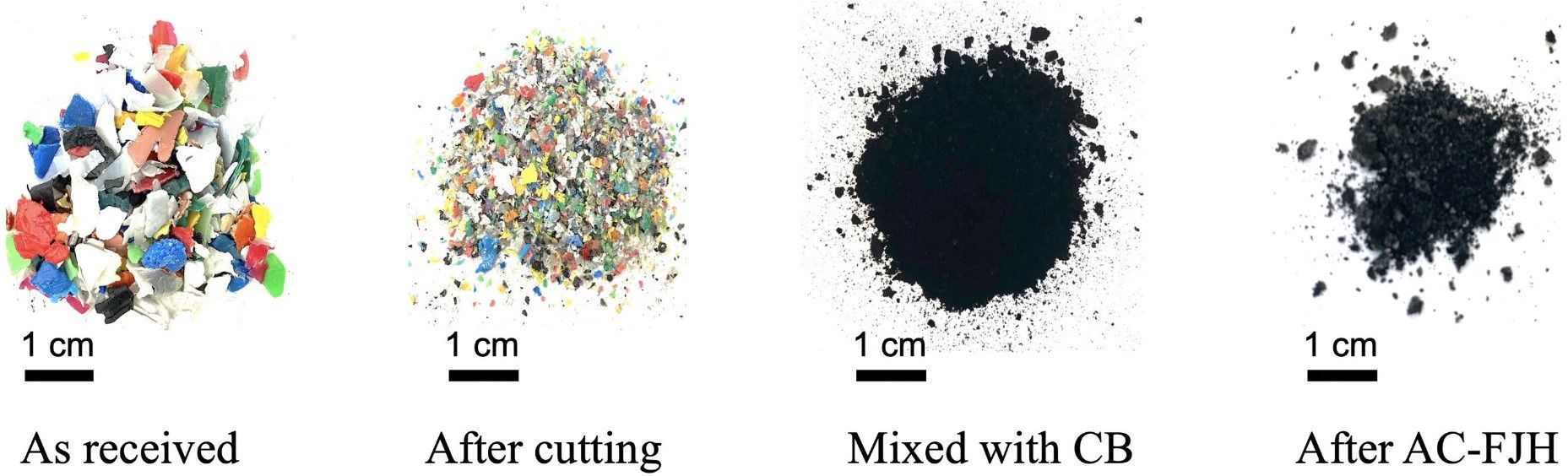

The changes to the ‘Flash Graphene’ procedure are described in the university press release as, “… instead of raising the temperature of a carbon source with direct current, as in the original process, the lab first exposes plastic waste to around eight seconds of high-intensity alternating current, followed by the DC jolt.”

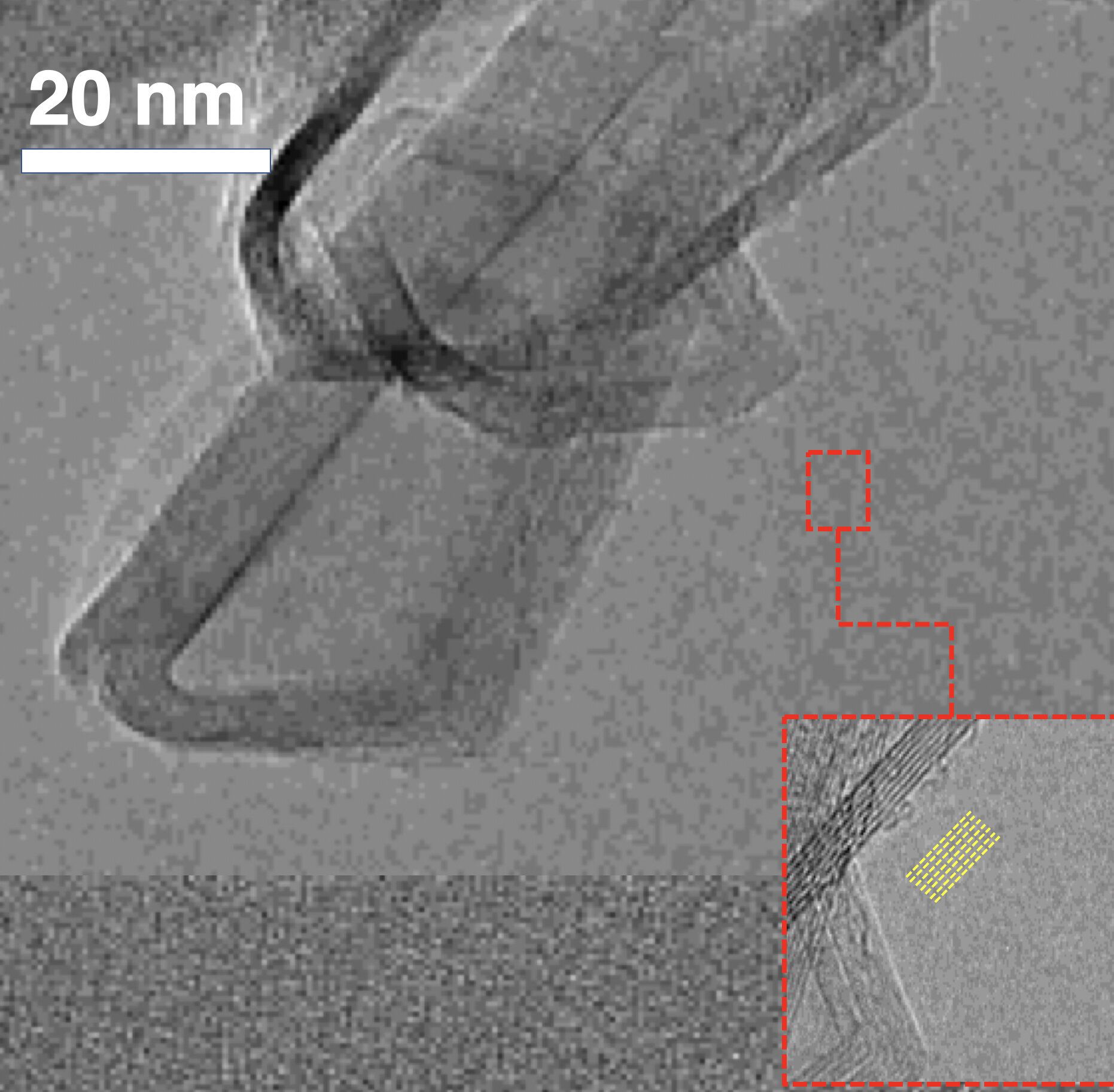

The result of this change is a nanotechnology method that produces ‘high-quality, turbostratic graphene’ from plastic waste.

“We showed in the original paper that plastic could be converted, but the quality of the graphene wasn't as good as we wanted it to be,” Tour said. “Now, by using a different sequence of electrical pulses, we can see a big difference.”

The team have also calculated the process to be financially viable at an industrial scale.

“Rather than recycling plastic into pellets that sell for $2,000 a ton, you could be upcycling to graphene, which has a much higher value,” Tour explains. “There's an economic as well as an environmental incentive.”

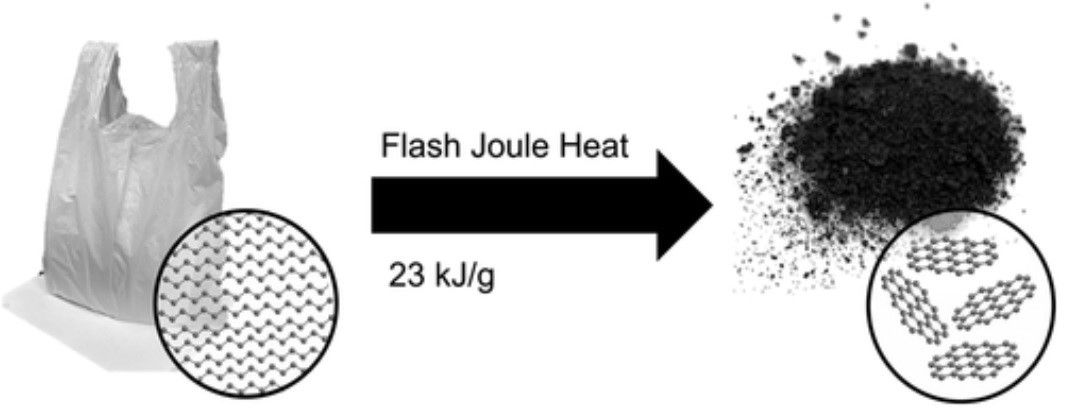

The study has now been published in the journal ACS Nano, where the researchers state, “In order to make high-quality graphene, a sequential alternating current (AC) and direct current (DC) flash is used. The flash joule heating (FJH) process requires no catalyst and works for plastic waste (PW) mixtures, which makes the process suitable for handling landfill PW. The energy required to convert PW to flash graphene (FG) is ∼23 kJ/g or ∼$125 in electricity per ton of PW, potentially making this process economically attractive for scale-up.”

However, it is clearly the environmental impact in finding a use for waste plastic that has inspired the team.

“Whatever you do with carbon, once you've taken it up out of the ground from oil or gas or coal, it ends up in the carbon dioxide cycle. The nice thing about graphene is its biological degradation under many conditions is very slow, so in most cases it doesn't reenter the carbon cycle for hundreds of years,” says Tour.

Furthermore, adds Wala Algozeeb, the study’s lead author, “We produce a considerable amount of hydrogen, which is a clean fuel, in our flashing process.”

Given the high quality of the graphene produced, waste plastic could be turned into raw material used in thousands of different applications, for use in electronics, chemical industry membrane filters, composites, drug delivery systems, solar panels, military and aerospace hardware, and even concrete.

Moving ahead, the team is now looking at how they can turn other waste materials into nanoproducts using the flash graphene process.

“We're working toward generating a good pulse sequence to convert food waste into very high-quality graphene with as little emission as possible,” Tour says. “We're employing machine learning programs to help us know where to go.”

Giving Waste Plastic New Life and New Properties

Meanwhile, in the Czech Republic, AG CHEMI GROUP, a Prague-based supplier of raw materials, has patents pending on a process that can give new life into waste plastic, even improving it at the same time.

Building on their more than 25 years’ worth of experience in supplying the plastics industry the company noticed an increase in demand for recycled feedstock.

Working with local nanotechnology researchers as well as scientists from Germany, Luxembourg, Russia, and the Ukraine the company (who sponsor this website) has now developed a process for boosting a polymer’s recyclability.

Whereas today, most plastics degrade when recycling as the polymer chains are corrupted in the recycling process, the latest nanotechnology allows for plastics to be given new qualities.

The process is called nanostructure technology, and it allows for the total modification of waste materials such as plastic in order to maintain the original properties of the material at a required level (for example, impact strength), as well as to add new material properties, such as thermal or electrical conductivity.

“The use of nanomaterials with a particle size in the nanometer range requires thorough preparation of the nanoadditive and pure polymer, as well as the use of special technology of two-phase modification, developed and tested by our company,” says Lev Lyapeikov, the product development manager at AG CHEMI GROUP. “Examples of the use of this technology can be found in our product portfolio and in our projects in the development and commercialization phase.”

To learn more about this topic, read: Nanostructured Polymers Give Plastic New Properties and New Markets

Photo credit: ACS Nano, freestocks.org from Pexels, Rice University and Tour Group, & Polina Tankilevitch from Pexels