Due to their increasingly widespread in the ongoing coronavirus pandemic designers everywhere are frantically working to improve mask performance.

One of the key issues to be solved is that many masks merely capture moisture droplets to prevent the spread of the virus. This has created a clear goal among mask manufacturers to create a face covering that kills the virus on contact with the material.

This issue is particularly relevant given the widespread use of disposable masks. These not only create a landfill problem but may also aid the spread of coronavirus if not properly disposed of.

Rising to this challenge has been a team of nanotechnology researchers from the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland.

As László Forró, head of EPFL's Laboratory of Physics of Complex Matter notes, “In a hospital setting, these [disposable] masks are placed in special bins and handled appropriately. However, their use in the wider world - where they are tossed into open waste bins and even left on the street - can turn them into new sources of contamination.”

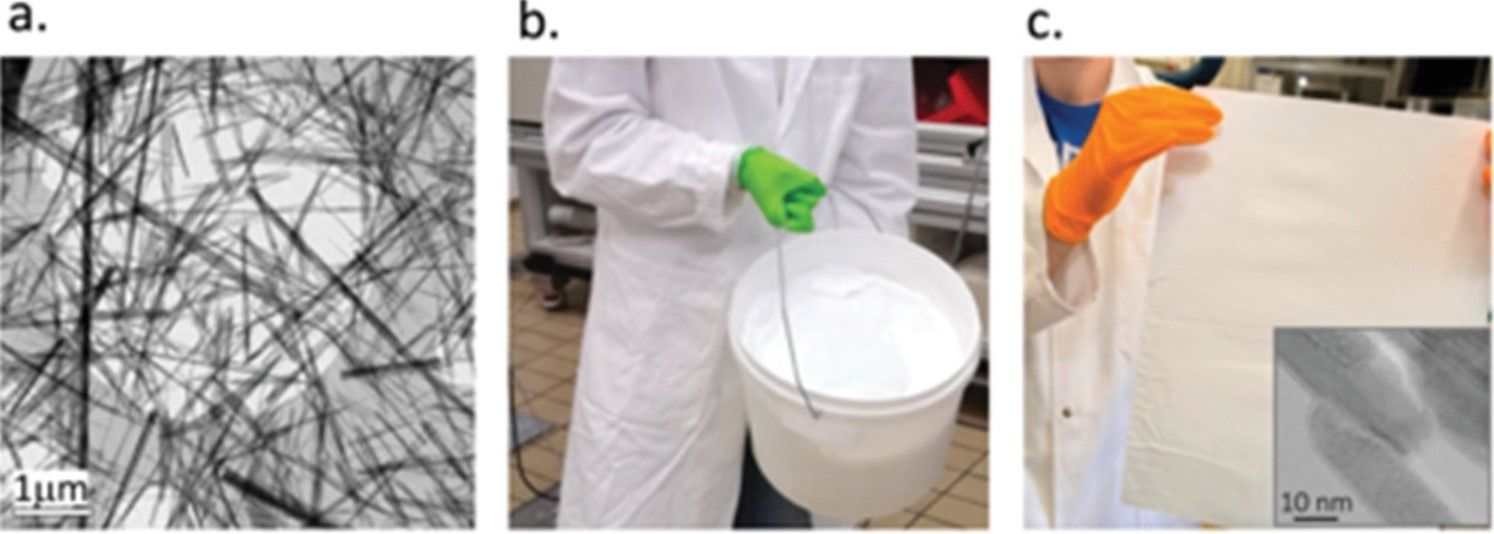

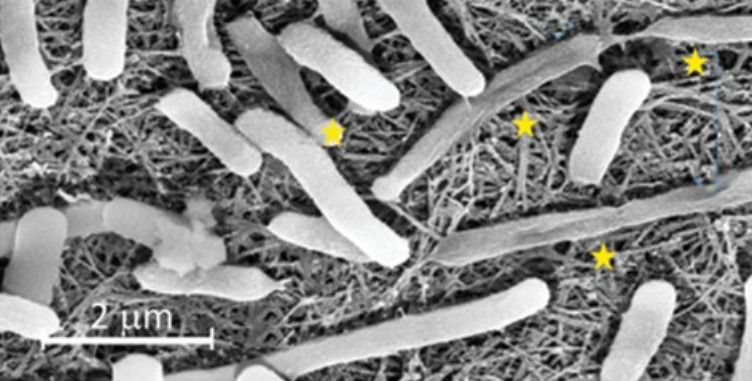

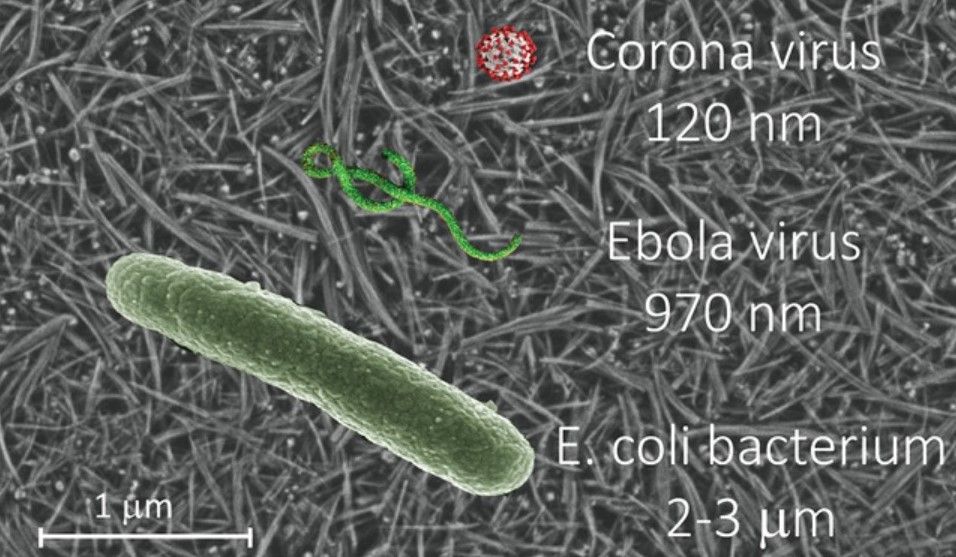

To solve this problem and to improve design in general, his team have created a face mask which incorporates titanium oxide nanowires directly inside the material. While the fibres of the mask are able to capture infected water droplets, the nanoparticles can destroy the virus (or other similar pathogen) when exposed to sunlight.

As the press release from the EPFL explains, “The reusable protective mask is designed around a membrane made of titanium oxide nanowires (TiO2NWs), similar in appearance to filter paper but with antibacterial and antiviral properties. This TiO2NWs-based filter paper works by using the photocatalytic properties of titanium dioxide. When exposed to ultraviolet radiation, the fibers convert resident moisture into oxidizing agents such as hydrogen peroxide, which have the ability to destroy pathogens.”

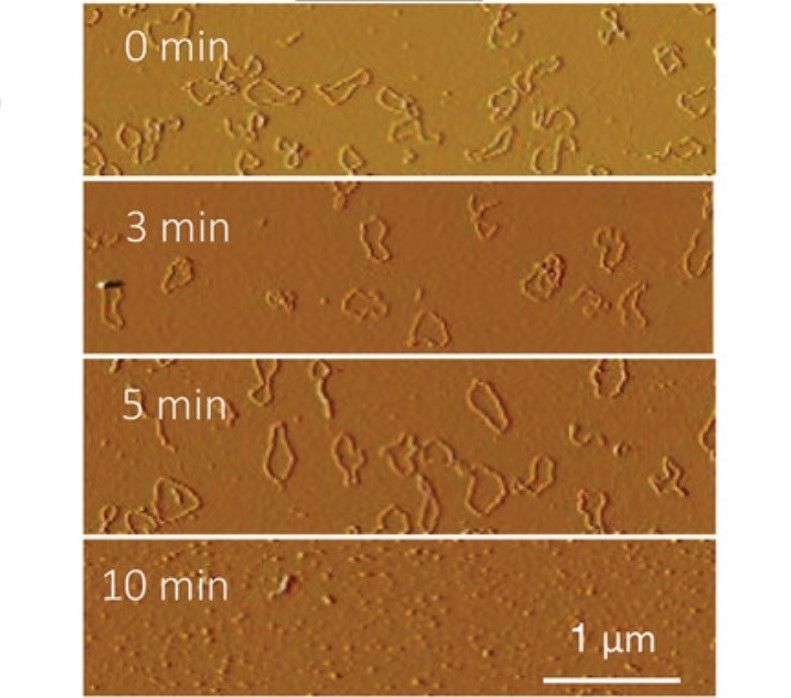

In experiments conducted at Forró's lab, a mask prototype was found to have disinfecting properties when placed under 365 nm UV illumination. The filtered germs are inactivated by reactive oxygen species (ROS), formed by a photocatalytic reaction on the surface of the filter material.

“Since our filter is exceptionally good at absorbing moisture, it can trap droplets that carry viruses and bacteria,” says Forró. “This creates a favorable environment for the oxidation process, which is triggered by light.”

“The membranes could also be used in air treatment applications such as ventilation and air conditioning systems as well as in personal protective equipment,” confirms Endre Horváth, the study's lead author.

The researchers have now published their findings in the journal Advanced Functional Materials where they note how the need for masks that can kill pathogens will be required even once the current pandemic has passed. Stating that, “The threats coming from microorganisms, viruses and bacteria are getting more frequent and more devastating lately, primarily due to the highly increased mobility of people and goods, which enhances the spread of infections. One may have in mind the outbreak of SARS‐CoV in 2004, of H1N1 in 2009, and the Ebola virus in 2018. In the case of bacteria, the O104:H4 strain of Escherichia coli caused causalities, but the danger is also coming from antibiotics resistant species like Legionella bacteria, Klebsiella pneumoniae, and Staphylococcus aureus.”

As such, there is clearly a need for more effective face masks, even if a cure for COVID-19 is found.

Significantly, the research team believe that the large-scale production of their mask design is easily achievable, as even in the laboratory, the team were able to manufacture up to 200 m2 of filter paper per week. This is sufficient raw material to make 80,000 masks.

Furthermore, the masks can be sterilised and reused, limiting the number that must be thrown away.

The team also observe how safe the masks are, as the production process involves ‘calcining the titanite nanowires’ which makes them more stable and prevents them being inhaled by the mask wearer.

Consequently, a start-up company has been formed with a view to begin production as soon as funding is complete.

A filter ‘paper’ that can catch and kill viruses and bacteria with light? Sounds like good business to me.

Photo credit: Wileyonlinelibrary, Anna Shvets from Pexels, & Karolina Grabowska from Pexels